Breaking Down Phosphorus Removal in Wastewater Treatment

Efficient phosphorus removal is a complex yet essential process for wastewater treatment facilities that have regulatory requirements. Facing fluctuating influent conditions, operational cost pressures, and regulatory requirements, many facilities struggle to effectively balance chemical and biological removal methods. But with the right approach and monitoring, these challenges can become opportunities for optimization.

The Basics of Phosphorus Removal

Phosphorus removal in wastewater treatment involves transforming dissolved phosphorus into particulate form, which can then be physically removed from the system. This can be achieved through chemical treatments, such as the use of metal salts, or via biological systems that leverage phosphorus-accumulating organisms (PAOs). Many facilities utilize a combination of the two, aiming for a cost-effective and reliable removal process.

Key Challenges in Phosphorus Removal

Several challenges can arise in the phosphorus removal process, including:

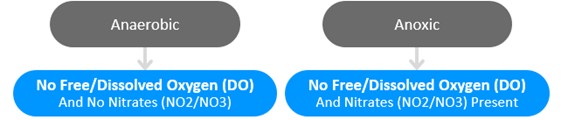

- Maintaining consistent anaerobic zones: Biological phosphorus removal is highly dependent on anaerobic conditions, which require the complete absence of both dissolved oxygen and nitrates. Any disruptions to these conditions can hinder the process.

- Balancing operational costs: Full chemical treatments are effective, but they can lead to high operating costs, including expenses associated with alkalinity reduction and pH adjustments.

- Environmental dependencies: Biological phosphorus removal is sensitive to environmental conditions, such as temperature, flow changes, and seasonal variations, making control and predictability challenging.

- Secondary phosphorus release: Processes such as secondary clarification can unintentionally release phosphorus back into the system if not managed properly.

- Optimizing hybrid systems: Combining chemical and biological treatments offers benefits but requires careful calibration to ensure cost-efficiency and reliability.

Optimizing Phosphorus Removal with a Holistic Approach

Protect the Anaerobic Zone

For successful biological phosphorus removal, the anaerobic zone must be carefully maintained and controlled. Factors to address include avoiding oxygen introduction, ensuring nitrate control, and providing adequate volatile fatty acids (VFAs). Without these measures, the process efficiency can drop significantly or fail.

Leverage Online Monitoring Tools

Real-time monitoring of critical parameters such as oxidation-reduction potential (ORP), nitrate concentrations, and phosphorus levels can provide actionable insights to enhance process control. Advanced monitoring tools make it easier to identify and respond to inefficiencies before they escalate.

Combine Processes for Greater Efficiency

Blending chemical and biological methods enables facilities to optimize phosphorus removal while managing costs effectively. For instance, biological methods can handle many treatment regulations when designed properly, while chemical treatments can act as a “trim system” to meet more strict effluent limits.

Turning Challenges into Opportunities

Adopting best practices in phosphorus removal involves not just addressing pain points but transforming them into pathways for improvement. Here’s what facilities can do today to enhance their processes:

- Conduct regular lab sampling to understand influent and process conditions for phosphorus and other operating parameters.

- Utilize advanced tools, such as online nutrient monitoring, for real-time data.

- Invest in operator training to ensure staff can adapt processes to changing environmental variables.

- Evaluate existing systems to identify potential efficiencies, such as optimizing recirculation pumps or reducing anaerobic mixing energy.

Effectively managing phosphorus removal demands a combination of expertise, advanced technology, and innovative solutions. To enhance your understanding and discover actionable strategies, watch our in-depth webinar on optimizing phosphorus removal systems.

Watch this Water Online webinar with Hach experts on Maximizing Phosphorus Removal.

Additional Resources

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Accurate Chlorine Measurement for Water Quality Monitoring

go to HACH.COMAccurate chlorine monitoring is crucial for maintaining compliant water quality and providing efficient process control, but choosing the right technology can be complex. Inaccurate readings can lead to regulatory issues, process inefficiencies, and...

Optimizing Water Quality: The Role of Total Suspended Solids and Turbidity Measurement

go to HACH.COMFor industrial facilities and municipal public works, maintaining water quality isn't just about protecting the environment. It's also critical for efficient operations, regulatory compliance, and financial stability. Exceeding discharge permit limits...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.