How Liquid-Phase H2S Monitoring Can Reduce WWTP Risk and Corrosion

At their best, wastewater treatment plants (WWTPs) can include hostile environments. At worst, they can be deadly if workers are exposed to hydrogen-sulfide gas that collects in confined spaces. Between those two extremes is a wide range of cost and performance circumstances that can be drastically impacted by accurately monitoring changes in wastewater composition that trigger fluctuating levels of hydrogen sulfide (H2S).

Why Liquid-Phase Measurement Makes a Difference

Until now, most WWTP operators have used gas-phase sensors or manual grab-samples to monitor hydrogen-sulfide concentrations in their applications. Electrochemical sensors that accurately monitor hydrogen-sulfide content in the liquid phase (Figure 1) make it easier to monitor precise levels via existing in-plant SCADA and PLC systems or cloud-based systems.

- Compared to gas-phase measurement, continuous liquid-phase measurement provides the true hydrogen-sulfide concentration in the water itself—a more consistent and reliable indicator than measuring diffused hydrogen-sulfide gas concentrations in the air above. That is because the rate at which H2S transfers from the liquid phase to gas phase—and the levels of concentration detectable in the air—can vary based on water/air temperature, turbulence that accelerates H2S off-gassing from the water, the distance of the sensor above the water, and ventilation of the air where H2S is measured.

- Compared to manual grab-sample testing —which is expensive, laborious, and a lagging indicator at best—continuous liquid-phase measurement provides more timely input for efforts to mitigate H2S levels related to odor and safety concerns. Taking those measurements at the headworks or even farther upstream in the collection system helps WWTP operators keep continuous track of the true concentration of H2S in water heading toward the treatment train.

Where Liquid-Phase Measurement Has An Impact

Because it measures the worst-case concentrations of H2S in wastewater in a matter of seconds, liquid-phase hydrogen-sulfide measurement taken directly in the wastewater flow can pay dividends throughout multiple aspects of WWTP operations:

- Timely, accurate, continuous readings pinpoint potential risks associated with dirty and dangerous maintenance activities in areas prone to hydrogen-sulfide accumulation or affected by fluctuations well beyond the routine daily concentrations.

- Having the ability to adjust and optimize chemical dosing according to changing hydrogen-sulfide concentrations—not just changing flow rates—can also help to cut chemical costs to a bare minimum without risking worker exposure to H2S or odor complaints from the general population.

- Providing an ongoing picture of changing concentrations also aids in minimizing corrosive damage to costly infrastructure, thereby reducing capital expenses for premature equipment replacement.

- Delivering precise insights needed to avoid overdosing not only cuts operating costs, but also minimizes risks of excessive chemical treatments upsetting critical biological treatment processes such as chemical phosphorus removal or chemically enhanced primary treatment (CEPT).

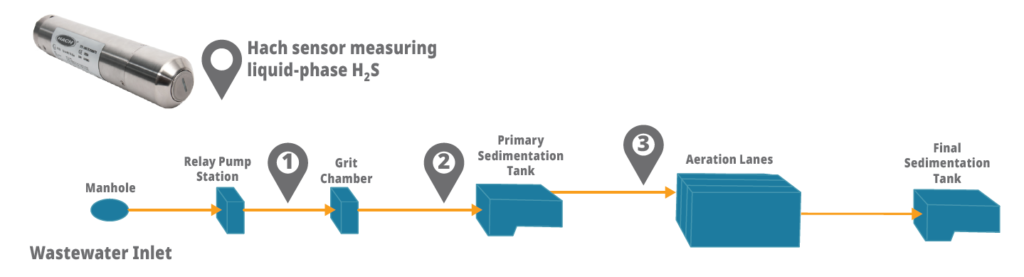

Striking an optimal balance between the worst-case concentrations detectable in the liquid phase and the most cost-effective chemical or aeration treatments creates operational benefits at key locations (Figure 2) throughout a WWTP:

Wastewater Treatment Plant

- Headworks Influent: Monitoring primary inlet pipes at the headworks of a WWTP sets the stage for protecting against downstream equipment corrosion, odor release, and potentially unsafe working conditions by matching chemical dosing to the actual exposure of H2S. And while monitoring influent at the headworks might be the easiest step to take, tracking inlet pipes from separate pumping stations can also help to provide better understanding of upstream effects and collection-network operations for better H2S control. For example, reducing lift-station thresholds for overnight pumping could change hydraulic retention time (HRT) enough to prevent a large surge of corrosive H2S from entering the treatment plant in the morning.

- Primary Clarifiers: Accurate liquid-phase measurement can offer multiple benefits of odor control and can warn operators of disruptions to biological treatment processes.

- Aeration Tanks: Liquid-phase monitoring of H2S in the aeration tank can also help to manage phosphorus and control struvite scaling there.

- Anaerobic Digesters: Using liquid-phase measurement in the bypass/recirculation pipe of an anaerobic digester can optimize timely dosing of air or sulfide-control chemical treatments to control anaerobic drivers as a way of suppressing odor release.

Avoid the Costs of Flying Blind

Beyond the problems of overpaying for chemical treatments, not having a continuous, accurate measure of changing H2S concentrations to guide treatment-plant decisions can also penalize operations by risking upsets in the following instances:

- Overdosing ferric salts for H2S control can bind up nutrients like phosphorus needed to support biological growth farther downstream in the treatment plant. Reducing nutrients beyond a certain point can hamper the ability to sustain the microbes that consume biochemical oxygen demand (BOD) in the wastewater.

- Over-reduction of volatile fatty acids in the wastewater flow can also disrupt the balance WWTPs rely upon for biological phosphorus removal.

- Development of unwanted filamentous bacteria—enabled by the reduction of single-cell or small-chain bacteria in the activated sludge process—can disrupt sludge-settling characteristics, thereby affecting clarifier operation and the quality of treated water.

Why Accuracy and Consistency Matter

And How To Achieve Them

The primary benefit to liquid-phase hydrogen-sulfide measurement is that it is the most accurate indicator of safety or corrosion risks relative to actual H2S concentrations—even if those conditions vary consistently by time of day or fluctuate wildly due to upset conditions. Being able to monitor conditions permanently, 24/7, establishes a better baseline for H2S control. Added flexibility from portability or dual-phase detection can further enhance other aspects of WWTP operations as well (Figure 3).

For example, the ability to move portable liquid-phase/gas-phase sensors to different locations for safety and odor-related assessments—especially sensors with cloud-based connectivity—extends capacity for cost-effective awareness of operating conditions throughout a WWTP. Operators can use them to evaluate existing hydrogen-sulfide control efforts or to test previously unmonitored locations in an effort to troubleshoot previously undetected problem areas.

Key Outcome: Continuous liquid-phase H2S monitoring provides the most reliable indicator of corrosion and safety risks, enabling optimized dosing, reduced costs, and better protection of infrastructure, workers, and community air quality.

Additional Resources

Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

go to HACH.COMIntroduction When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering...

Maximizing Phosphorus Removal

go to HACH.COMPhosphorus removal plays a critical role in protecting waterways, meeting permit requirements, and managing treatment costs. But optimizing phosphorus treatment isn’t always straightforward, especially when processes, influent conditions, and system...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.