Achieving a Delicate Balance to Maintain RO Membranes – Semiconductor, Chemical, & Beverage

Application Note: SBS Overfeed/Underfeed

Reverse Osmosis (RO) is used for water purification in various municipal and industrial applications. Ultrapure water (UPW) used for semiconductors, chemicals, or beverage production has strict limits on the presence of contaminants and therefore RO filtration is frequently involved in UPW preparation cycle. Normally, the source water is chlorinated and then, to prevent premature RO membranes degradation, the feedwater must be dechlorinated. Dechlorination can be conducted via adsorption or chemical addition (usually sulfite-based reagents) and disinfectant residual in feedwater water must be thoroughly monitored and controlled. Multiple studies showed that prolonged exposure of RO membranes to chlorine is detrimental to the membrane structure and integrity, while absence of the disinfectant promotes biofouling and causes loss of recovery. To maintain this delicate balance, the operators must be able to accurately monitor oxidant concentration and addition of dechlorinating chemicals.

Problem

The issues related to underfeeding dechlorinating agents manifest in creating an excess of chlorine attacking the RO membrane’s polymeric structure and causing irreversible damage. This affects salt rejection rate and shortens the membranes life span. The rule of thumb is that common RO membranes lose 50% of their salt rejection ability if exposed to a 1000 ppm-hr of chlorine over 3 years1. This translates to 38 ppb of ongoing chlorine exposure over the membrane life.

On the other hand, overfeeding the most common dechlorinating chemicals based on sulfite leads to increase in biofilm formation due to the lack of disinfectant in the water. Besides the increase in common biofouling, excess of sodium bisulfite (SBS), for instance, leads to depletion of dissolved oxygen and proliferation of sulfur-reducing bacteria (SRB) in the water. SRB can cause problems, including microbially influenced corrosion, rotten egg smell due to formation of hydrogen sulfide (H2S), slimy coatings, and brown foaming. Therefore, overfeed of SBS, besides added cost, may lead to multiple detrimental consequences and increased biofouling. The latter will diminish the RO membranes performance (flux) necessitating effective pretreatment, monitoring, and cleaning strategies to mitigate its effects.

Solution

The need to maintain disinfectant residual to keep biofilm from growing excessively but at/below 38 ppb to ensure life expectancy of the RO membranes, dictates the necessity to monitor residual chlorine accurately at such low levels. The Ultra-Low Range (ULR) CL17sc chlorine analyzer uses colorimetric method to measure total chlorine residual with unparalleled accuracy provided by the low limit of detection (LOD) of 8 ppb. This means that the readings at or above LOQ (limit of quantitation) ~ 3 x LOD are accurate within +/- 8 ppb or 5%, whichever is greater. Accurate chlorine readings provided by the analyzer every 150 seconds (2.5 minutes) will show a complete picture of the dechlorination process, detect any excursions of chlorine above the set limit, and help to manage RO membranes properly. In addition, the analyzer’s function calculating total chlorine exposure (Cumulative Chlorine Counter) shows on screen how much chlorine has passed through the membrane at any given time.

Even if a utility targets zero chlorine, we need to remember that zero is never a zero, but as close to it as we can measure. The ULR CL17sc with LOD of 8 ppb can measure much closer to zero or other target chlorine level yielding actionable insights and providing confidence in its readings. Without such confidence tied to the right specifications, you may be breaching your target, putting your system at risk, or incurring additional direct or indirect costs by overfeeding or underfeeding dechlorinating chemicals. All this will help to ensure specified quality of RO feedwater, of produced UPW, and by extension the quality of the manufactured products ranging from semiconductors to drinking water.

Case Studies

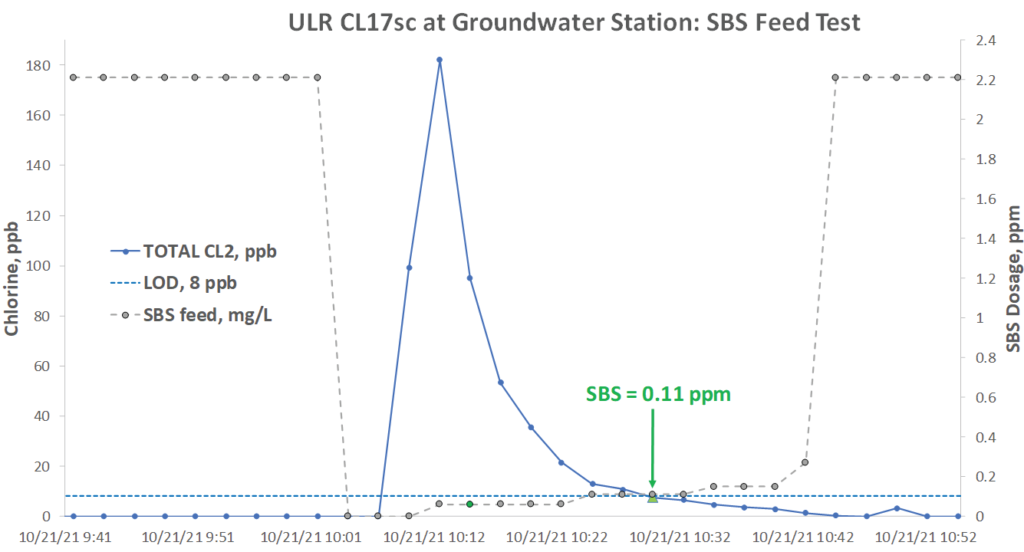

A study conducted at groundwater stations in El Paso, TX employing RO filtration to remove arsenic, demonstrated ability of the ULR CL17sc to detect chlorine accurately at the low-ppb levels. The utility chlorinates groundwater to disinfect and oxidize arsenic into a removable form. Then the water is dechlorinated with SBS prior to microfiltration and RO membranes. A sensitivity test was performed to determine optimal SBS feed (Figure 1).

The test demonstrated that optimal SBS feed rate was 0.11 ppm, while it was pre-set at 2.2 ppm. Thus, the SBS overfeed was more than 20 times of the safe level. The safe level was determined to be at and slightly above 8 ppb that is the analyzer’s LOD which demonstrates definitive presence of chlorine to maintain disinfection, while being well below the 38-ppb threshold. Just the SBS cost savings of such process optimization would be significant enough to justify implementation of ULR CL17sc analyzer.

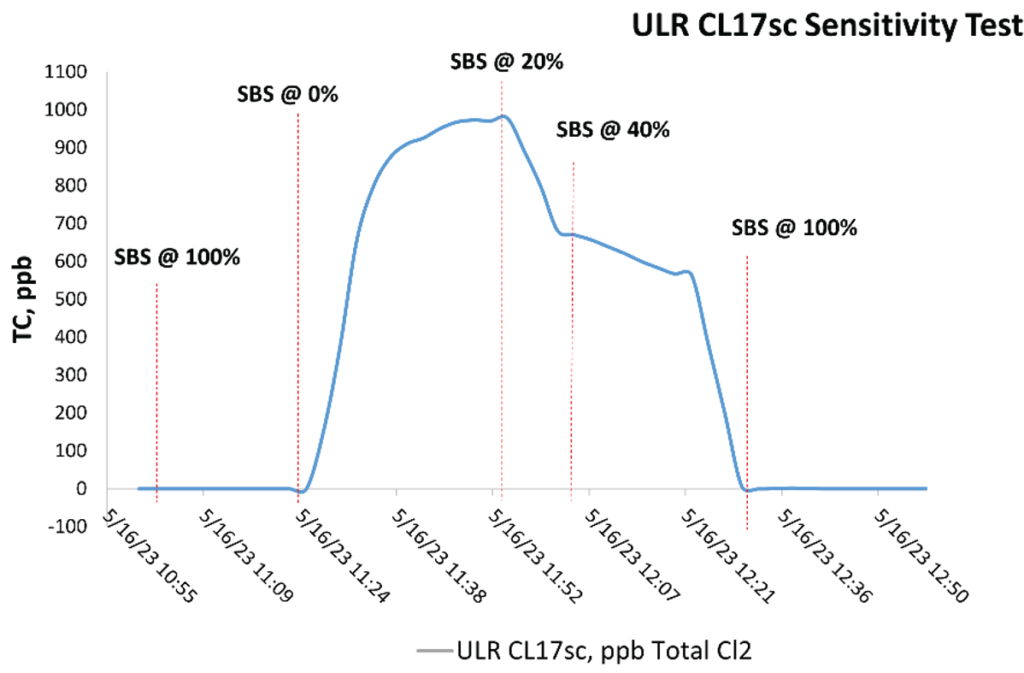

Another study conducted at a semiconductor manufacturing facility was to help optimizing their SBS feed control in the UPW preparation cycle. At the time of test, the UPW personnel relied on a standard CL17 and an ORP sensor to monitor and control dechlorination. Application of the ULR CL17sc in combination with DR1300 FL handheld fluorometer helped to keep the SBS feed under tighter control.

The personnel knew they were overfeeding SBS, however could not quantify it using standard instrumentation. A test involving ULR CL17sc was conducted to quantify the overfeed and optimize it. The test results (Figure 2) showed that optimal SBS feed to maintain ~40 ppb residual chlorine would be at 60-70% of the current rate, which would provide significant chemical cost savings justifying implementation of the ULR CL17sc analyzer. After the test, the UPW facility management decided to halve the SBS feed rate and purchased the analyzer.

Outcomes

As demonstrated by the conducted field testing, implementation of ULR CL17sc for monitoring of RO feedwater dechlorinated with SBS can save enough money only on the chemicals to justify purchase of the analyzer. The instrument will provide highly accurate direct chlorine measurements at minimal maintenance efforts supporting all chemical and labor cost savings and projecting the full ROI in two years on average.

- Chlorine dose calculated per hour of membrane operation that amounts to a 1000 ppm accumulation during a 3-year span, assuming continuous duty.↩

Additional Resources

Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

go to HACH.COMIntroduction When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Breaking Down Phosphorus Removal in Wastewater Treatment

go to HACH.COMEfficient phosphorus removal is a complex yet essential process for wastewater treatment facilities that have regulatory requirements. Facing fluctuating influent conditions, operational cost pressures, and regulatory requirements, many facilities...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.