Optimization of a Biological Treatment Plant in the Pulp and Paper Industry

Problem

Sludge quality fluctuations and filament growth resulted in sludge drain and high pollution levels, including TOC (Total Organic Carbon).

Solution

Continuous, on-line monitoring of the biological treatment plant load and nutrient levels in the effluent enables better plant control. The resulting high quality sludge improves plant efficiency and effluent quality.

Benefits

Smurfit Kappa Piteå can increase the production of kraftliner without exceeding discharge standards.

Background

Smurfit Kappa Piteå is the largest kraftliner mill in Sweden with an annual production of about 800,000 tonnes of kraftliner in different designs, bleached and unbleached pulp with recycled fiber of different levels depending on the paper quality. Smurfit Kappa Piteå has two liner machines that produce the different paper qualities.

They intended to improve the management and regulation of the biological treatment plant so it could handle the resulting load variations in the best way. The goal was to get a stable operation of the biological treatment plant with a uniform sludge quality and discharge levels well below the stipulated regulatory requirements.

Problem

Smurfit Kappa Piteå had for some time experienced fluctuations in sludge quality in the biological treatment, and therefore the function of the biological treatment plant was not reliable. Smurfit Kappa Piteå had trouble meeting discharge requirements as TOC levels added load on the biological treatment plant. They investigated the cause of the problem and implemented a number of improvements, one of which was to improve the control of the nutrient dosing in the biological treatment plant.

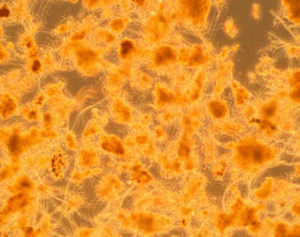

Previously, Smurfit Kappa Piteå used the flow into the biological treatment plant and laboratory values of TOC to control a number of nutrients dosed. Underdosing of nutrients results in filament growth and scum, overdosing results in increased chemical costs and denitrification, which in turn can lead to filament buildup and floating sludge problems.

The intention was to supplement existing metering of nutrients by measuring TOC on the incoming water stream to the biological treatment and so to monitor the load continuously. They previously used production speed of the paper machines as a decisive parameter relating to the nutrient dosing. High demands are made on the TOC Analyzers’ accuracy, accessibility, and user-related supervision.

Solution

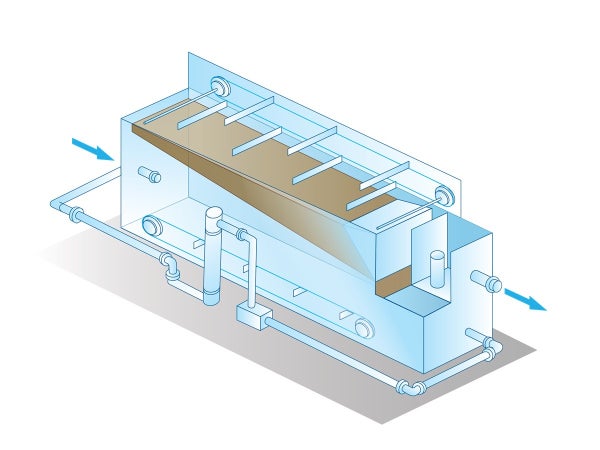

Smurfit Kappa Piteå had previously mounted instruments from Hach® for phosphate (Phosphax sigma), ammonium (Amtax sc), and nitrate (Nitratax plus) combined with filtration equipment for pretreatment of samples (Filtrax). The analytics instrumentation fleet was extended to include a TOC analyzer (BioTector B7000). This provides a complete analytics suite to most efficiently control nutrient dosing.

The water to be analyzed places high demands on the pretreatment and analysis equipment to be used. The quality of water to be analyzed places high demands on both the pretreatment and analysis equipment due to residual fiber fragments, filler particles, and chemical residues.

Previous tests with high-temperature technology TOC analyzers proved unsatisfactory as hose blockages and crystallization in the furnace resulted in breakdowns and low uptime.

Uptime considerations have been overcome with the new, two-stage oxidation technology from Hach. This provides complete oxidation of the sample, measurement accuracy, and the uptime performance needed and already demonstrated by the other Hach analyzers installed on site. Smurfit Kappa Piteå are fully confident in the online data provided and that consistently correlates with laboratory cross-checks.

Mounting

Benefits

Smurfit Kappa Piteå has, by ensuring a continuous accurate and reliable analysis of TOC and nutrients, been able to control its biological treatment so that it is now capable of handling the wide variations in incoming water quality.

The previous problems of potentially exceeding discharge consents, and higher than necessary chemical usage due to sludge quality issues and overdosing have been stopped and the biological treatment plant performance improved.

| Aspect | Before Installation | After Installation |

|---|---|---|

| Sludge Quality | Frequent filament growth, scum, and floating sludge problems | Dense flock formation, fewer filaments, stable sludge |

| Discharge Compliance | Risk of exceeding discharge consents due to TOC fluctuations | Consistently meets discharge requirements |

| Chemical Usage | Overdosing increased costs and caused denitrification issues | Optimized dosing reduced chemical consumption and costs |

| Uptime | Frequent downtime with high-temperature TOC analyzers | High uptime with two-stage oxidation BioTector B7000 |

Summary

After the changes made by the installation, commissioning, and implementation of the new BioTector B7000 online analytic system, Smurfit Kappa Piteå is now able to meet discharge requirements. The site is now well equipped to cope with future increases in production without compromising on internal requirements for environmentally sustainable production of the highest quality kraftliner.

Key Outcome: Smurfit Kappa Piteå maintained 800,000 tonnes/year kraftliner production while consistently meeting discharge requirements, ensuring both regulatory compliance and sustainable growth capacity.

Additional Resources

Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

go to HACH.COMIntroduction When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Deep Dive into Online Chlorine Monitoring

go to HACH.COMAccurate chlorine monitoring is essential for regulatory compliance and process control in municipal and industrial applications. Choosing the right analyzer can help reduce chemical costs, minimize downtime, and ensure consistent water quality. Join...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.