Manage Product Loss and Protect Profits in Pulp and Paper Manufacturing by Monitoring Nutrients and Solids

Not only is product loss wasteful in the short term, it can also indicate a chronic underlying issue—such as a process inefficiency or mechanical breakdown—that could have staggering consequences in the long term. Plant managers can gain valuable insight into plant operations by tracking product loss over time, which can be done simply by collecting and tracking data in two key areas.

- Nutrient Optimization

- Solids Management

Nutrient Optimization

Secondary biological treatment of P&P wastewater depends on healthy bacteria to remove biodegradable organic matter and reduce toxicity, but nutrient dosing is a delicate balancing act.

Using an excess of nutrients is not only wasteful, but also leaves residual ammonia and orthophosphate in the effluent, which must be removed prior to discharge.

If nutrient levels are too low, however, treatment efficiency drops—even to the point of ineffectiveness—resulting in higher effluent total suspended solids (TSS) and biological oxygen demand (BOD). Indicators of nutrient-limited conditions include:

- Foaming and excess polysaccharide production

- Improper settling or dewatering

- Overgrowth of filamentous bacteria compared to floc-forming bacteria

Without adequate nitrogen and phosphorus, bacteria are unable to completely break down complex toxic organic molecules into simpler, less harmful compounds. Even a slight nutrient deficiency can mean that toxic substances are passing through untreated into the final effluent, resulting in higher production costs for post-treatment chemical dosing, or potential fines and downtime resulting from exceeding permit values.

Popular Nutrient Optimization Strategies

Control to Residual Targets

Most effluent treatment systems manage their nutrient feed by measuring nutrient residuals and then adjusting them based on residual control targets. This can be an acceptable management strategy, assuming that the popular residuals are measured in the proper location at a proper frequency (daily, at a minimum).

This strategy is reactive: operators react to residual levels by changing nutrient feed rates. If a residual is high, operators will decrease a feed rate; if residual is low, operators will increase a feed rate.

Pros: The risk of overfeeding or underfeeding is minimized because dosing is closely matched to nutrient requirements based on organic loading and aeration basin performance.

Cons: The potential for inaccurate readings and slow response times is high, depending on where and when measurements are taken.

Control to BOD:N:P Ratio

Nutrient feed may also be calculated as a ratio of biological oxygen demand to nitrogen to phosphorus in activated sludge. The recommended guideline is BOD:N:P of 100:5:1. Depending on the type of mill and treatment system, the proportion of nitrogen could range from 4.5 to 4.8, while the proportion of phosphorus could range from 0.5 to 0.8.

Pros: An established BOD:N:P enables nutrient feed that is closely matched to organic loading, resulting in nutrient cost savings and lower risk of nutrient deficiency.

Cons: Direct BOD testing has a 5-day lag time, therefore plants that employ this strategy must correctly correlate BOD with COD, TOC or 1-day BOD measurements. Poor nutrient management will occur if good correlations have not been established.

Alternative Nutrient Optimization Strategies

Residual Feedback to BOD:N:P Feedforward

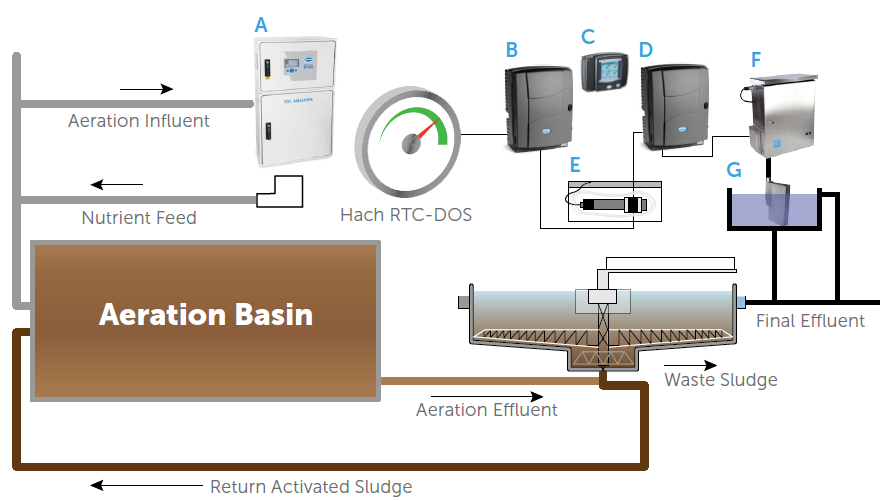

Online TOC or UVAS measurements can be used by a Hach® RTC-DOS module to determine the optimal C/N/P ratio for carbon removal and automatically deliver the correct dose of phosphorus and nitrogen sources. The system continually detects phosphate and inorganic nitrogen and uses this feedback to further optimize the biological treatment process.

Pros: Nutrient dosing rates are continuously adjusted based on real-time organics load and residual nutrients, resulting in stabilized and compliant purification performance and sludge characteristics. “Off-the-shelf” system with simple set-up; little to no maintenance, training and staff oversight required.

Cons: Requires RTC-DOS module; may require additional instrumentation. (Please refer to the Recommended Instrumentation section below.)

RTC-DOS features:

- Up to 4 different specific dosing rates N/BOD and P/BOD for different products

- Up to 4 TOC-UVAS/BOD relationships applicable

- Allows the operator to split the calculated nutrient dose rate into two dosing points

- Considers hydraulic retention time

- Option for load-based inflow distribution to selectors / aeration step

- F/M ratio calculation based on TSS (MLSS) and TOC inflow concentration

- Option for airflow monitoring to identify load peaks

Solids Management

Solids in P&P wastewater refer to excess pulp fibers that have escaped the production process and are on their way to becoming waste instead of saleable product. Careful monitoring of solids can help:

- Optimize the save-all operation. Maximize resource utilization by recovering more fibers on the paper machine water loop.

- Optimize the sludge dehydration process. Maximize efficiency either by improving the BTUs of boiler fuel or by decreasing the cost of transportation and disposal.

Popular Solids Management Strategies

High-Pulp Consistency Meters

Most plants use high-pulp consistency meters to measure suspended solids and control their production. However, these meters are expensive, cannot measure low concentration, and are bolted to the pipes without the option to perform maintenance during runtime.

Alternative Solids Management Strategies

Optical Probe

A versatile, low-cost suspended solid probe, such as the Hach TSS sc, enables plant operators to measure solids at more points throughout the production process without the financial or maintenance burden of a high-pulp consistency meter.

Examples of applications of a suspended solids probe include:

- Measuring the solids at the effluent of each plant department for solids management, product loss optimization and troubleshooting.

- Improving the efficiency of the pulp thickeners.

- Monitoring and controlling of the kraft green (dregs) and white liquors (lime mud) clarifiers.

- Measuring the first pass retention on the paper machine with solids measurement at the headbox and wire pit.

- Measuring the efficiency of and controlling the save-all and coag/polymer dosage.

- Measuring the efficiency of the wastewater clarifiers and final effluent for regulation.

- Measuring WAS, RAS, MLSS and sludge retention time in the biological activated sludge reactor.

- Measuring sludge consistency and filtrate quality on the dehydration press for efficiency and coag/polymer dosage.

Recommended Instrumentation

Instrumentation for Nutrient Optimization with Hach RTC-DOS

- A. BioTector® B7000i

- B. Phosphax Orthophosphate Analyzer

- C. SC1000 Controller

- D. Amtax Nitrogen Ammonia Analyzer

- E. Nitratax Nitrite/Nitrate UV Probe

- F. Filtrax Filtration Control Unit

- G. Filtrax Filtration Sample Pump

- Hach BioTector® B7000i for Total Organic Carbon – self-cleaning oxidation technology, multi-stream capability, measures carbon, nitrogen, phosphorus

- Hach Phosphax sc for Orthophosphate – high-precision analyzer, detection limits as low as 0.05 mg/L, fast response

- Hach Amtax sc for Ammonium – selective gas-sensitive electrode, automatic cleaning and calibration

- Hach UVAS sc – reagent-free SAC/UV254 measurement, robust and low maintenance

Instrumentation for Solids Management

Hach TSS sc Suspended Solids Probe – versatile, robust optical probe with wide measuring range (0.001–500 g/L), resistant to fibers, chemicals, and harsh conditions.

Hach Value-Adds

Hach Prognosys™ Predictive Diagnostics

Prognosys is a predictive diagnostic system that allows you to be proactive in your maintenance by alerting you to upcoming instrument issues. Prognosys allows pulp and paper mill managers to know with confidence whether changes in their measurements are due to changes in the instrument or changes in the water.

Prognosys displays two status indicators for every connected Prognosys Enabled instrument. These indicators give operators all the information they need to plan preventive maintenance and avoid unexpected emergencies. The measurement indicator monitors the instrument’s components and uses that information to alert the user to upcoming instrument needs before measurements become questionable. The service indicator tracks the number of days until the instrument will require maintenance.

Hach ServicePlus®

Hach’s complete Service package includes routine maintenance visits and warranty repairs. A team of remote technical experts will monitor your system and send you reports so you know your system is working properly. It’s like having a Hach Technician at your facility.

Conclusion

Measuring product loss is about more than plant performance: it can maximize yield and resource utilization, minimize operating expenses, and provide advance warning of costly process issues and mechanical breakdowns.

Even better, staying on top of these important concerns can be achieved with two simple measurements—and two solutions from Hach. RTC-DOS for nutrient optimization allows P&P managers to benefit from a continuous adjustment of dosing rates based on real-time organics load and residual nutrients. The TSS sc line of probes provides a low-cost, wide-ranging versatility for solids management. Used together with Prognosys, these solutions can help achieve more stable performance, more uptime and more confidence in meeting nutrient residual regulation levels.

Business Impact: Better nutrient and solids monitoring reduces product loss, lowers operating costs, and ensures compliance—helping pulp and paper manufacturers protect profits while achieving stable, sustainable operations.

Find complete water analysis solutions for the pulp and paper industry at hach.com

Additional Resources

Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

go to HACH.COMIntroduction When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Breaking Down Phosphorus Removal in Wastewater Treatment

go to HACH.COMEfficient phosphorus removal is a complex yet essential process for wastewater treatment facilities that have regulatory requirements. Facing fluctuating influent conditions, operational cost pressures, and regulatory requirements, many facilities...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.