Controlling Post GAC Chlorine Levels in a Beverage Facility at High Ambient Temperatures

Ultrapure water (UPW) used for semiconductors, chemicals, or beverage manufacturing has strict limits on the presence of either oxidants or reducers, and dechlorination is frequently done with granulated activated carbon (GAC) adsorbing chlorine, either followed by reverse osmosis (RO) membrane filtration or not. Whether dechlorinating via adsorption or chemical addition (sulfite-based reagents), regardless of the use of RO membranes downstream, disinfectant residual in production water must be thoroughly monitored and controlled. Currently, such monitoring and proportional addition of dechlorinating agents is mostly done with either grab sample analysis, or its combination with continuous oxidation-reduction potential (ORP) measurement. Measuring chlorine residual with direct colorimetric analysis has many advantages over e-chem methods, allowing to provide accurate results and differentiation between chlorine species should it be necessary. For example, total chlorine analysis allows the measurement of free chlorine only, or of chloramines, or of all chlorine species, or along with other oxidants present in the water (TRO = total residual oxidant). All these oxidants may be detrimental to the RO membranes, the produced water, or the manufactured goods. Therefore, total chlorine measurements provide the necessary assurance in any membrane protection applications, especially after adsorption-based dechlorination, which can create various chloramines, the presence of which may be missed by free chlorine only methods.

Background

A post-GAC chlorine residual test using Hach® Ultra-Low Range (ULR) CL17sc chlorine analyzer was conducted at a major beverage manufacturing facility. The measurements had to be accurate because chlorine levels post GAC were required to be below 60 ppb for the water to be used in bottling and syrup production. Additionally, the analyzer had to operate at fringe specifications due to high ambient temperature at the facility, which was between 35-40°C on average and temporarily reached 53°C during weekly steam cleanings. At the time of testing, dechlorination by GAC (no RO involved) was monitored only by laboratory (grab sample) tests which the facility management considered to be inadequate for measuring residual chlorine levels in this low range.

Solution

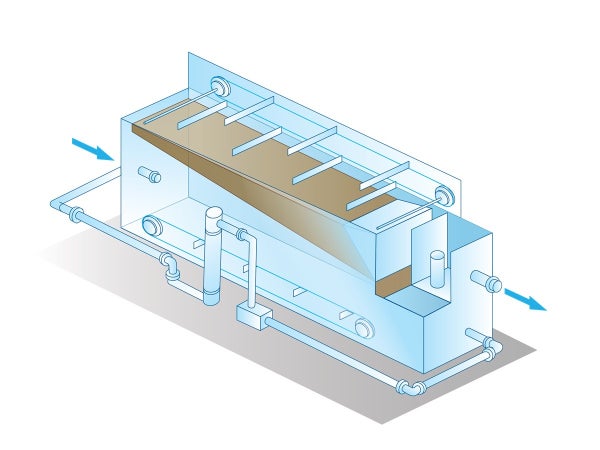

The Hach ULR CL17sc chlorine analyzer was used at this location to meet the criteria established by production. The analyzer uses colorimetric methods to measure total chlorine residual with unparalleled accuracy provided by low limit of detection (LOD) of 8 ppb. This means that the readings above ~3 x LOD = LOQ (limit of quantitation) are accurate within +/- 8 ppb or 5%, whichever is greater. Therefore, accurate chlorine readings provided by the analyzer every 150 seconds (2.5 minutes) will show a complete picture of the dechlorination process, detect any excursions of chlorine above the set level, and help to manage GAC tanks/beds properly. All this will help to ensure specified quality of the water used for bottling and syrup production at this facility.

Results

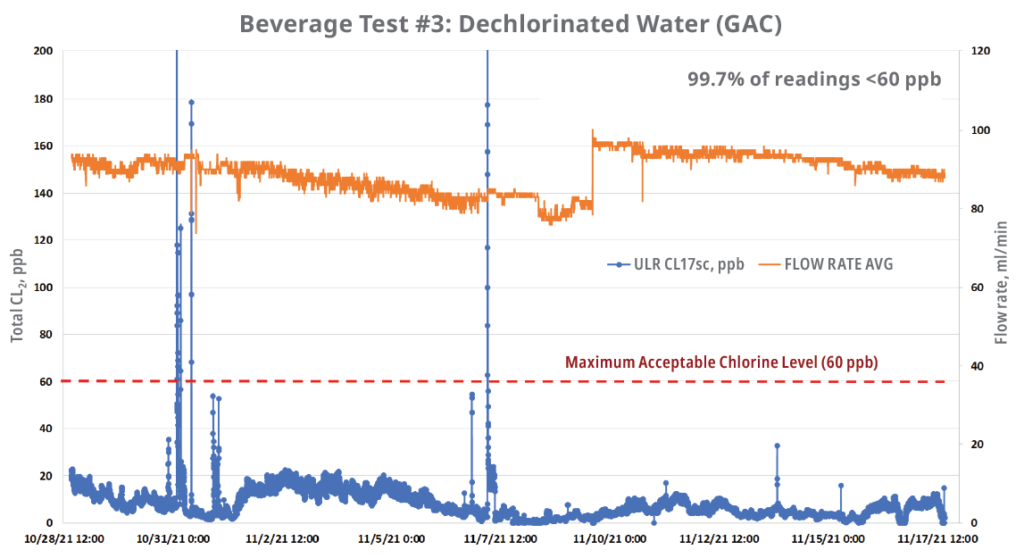

The Hach ULR CL17sc provided continuous measurements of total chlorine concentration after the GAC and polishing filters and before UV disinfection. The stable flow and deeper data analysis confirm the process-related origin of the spikes with a maximum chlorine concentration of 0.55 ppm (Figure 1).

Given the infrequent and short-lived nature of such spikes, as well as high dilution rate as confirmed by the average residual (8 ppb), it is safe to assume no harm to the production water. Additionally, despite the elevated ambient temperatures*, data from the analyzer demonstrated reliable dechlorination from GAC to target levels.

*NOTE: The operating and sample temperatures should be kept below 40°C to ensure the analyzer will measure within specification. Elevated ambient temperatures may cause a high measurement bias as the DPD reagents near the end of their 30-day life cycle.

General Conclusions

The evaluation of the Hach Ultra-Low Range CL17sc at this facility demonstrated the analyzer’s ability to provide users with credible and reliable chlorine data at part-per-billion levels, even in challenging conditions encompassing intermittent flow/operation and elevated ambient temperatures. The data generated by the analyzer at different points of beverage production can be used to ensure dechlorination efficiency, enhance quality assurance programs, improve process control, and protect chlorine-sensitive equipment. Thus, the ULR CL17sc ultra-low range chlorine analyzer may provide significant operational cost savings and protect capital investments.

The ULR CL17sc has LOD of 8 µg/L (ppb) and accuracy of ±5% or 10 ppb, whichever is greater. The CL17sc has LOD of 30 µg/L (ppb), and accuracy of ±5% or 40 µg/L (ppb), whichever is greater. Depending on your targeted chlorine level, specified LOD or accuracy yields actionable insights and provides confidence that you are below your residual target. Without such confidence tied to the right specifications, you may be breaching your target, putting your system at risk, or incurring additional cost by overfeeding dechlorinating chemicals.

Additional Resources

Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

go to HACH.COMIntroduction When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Deep Dive into Online Chlorine Monitoring

go to HACH.COMAccurate chlorine monitoring is essential for regulatory compliance and process control in municipal and industrial applications. Choosing the right analyzer can help reduce chemical costs, minimize downtime, and ensure consistent water quality. Join...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.