Final Product Quality Control In Brewing

The hop processing company, Hopfenveredlung St. Johann is processing around 25,000 metric tons of hops per year into pellets. At their production site in St. Johann, Hallertau, Germany, they run a state-of-the-art pilot brewery. One of the key functions of the pilot brewery is to run trials on a variety of brewing functions, including raw product (hops and hop products) and technology (including bottling, brewing and analytical instrumentation), as well as product development. These trials are done for the shareholders Barth Haas Group and HVG and other breweries or suppliers on a contract basis.

Recently, the facility had the opportunity to test a KRONES semi-automatic bottling device. This was done to ensure that the equipment on hand would meet the reproducibility standards set by the pilot brewery. To test the instrument, the brewery set up an Orbisphere 6110 Total Package Analyzer. During this test, the facilitator pulled every 15th bottle from the line, resulting in 750 bottles being tested over a period of two days.

The bottler was filling standard 0.33 liter (11.2 oz.) longneck bottles with lager beer. Every 15th bottle was pulled from the line after it was filled, and was tested with the Orbisphere 6110 for its Total Packaged Oxygen (TPO), its CO2content and its filling volume. This lab equipment enables an operator to measure the following parameters at once in a short measurement time:

- O2 in the headspace and in the liquid

- CO2 in the headspace and in the liquid

- Filling volumes of the bottles/cans tested

The instrument allows beverages to be analysed without removing any product from the container. Further, there is no direct contact between the liquid and the sensing technology, as all the measurements are taken in the gas phase. The individuals running the test over the two days found the equipment to be very easy to use: it only required that the bottle be set in the instrument, and a button pushed.

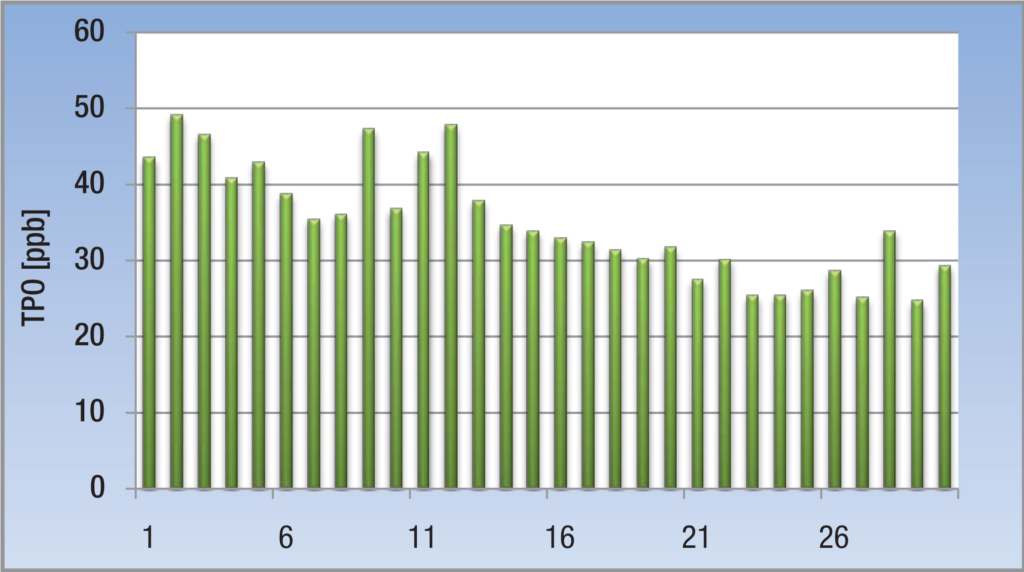

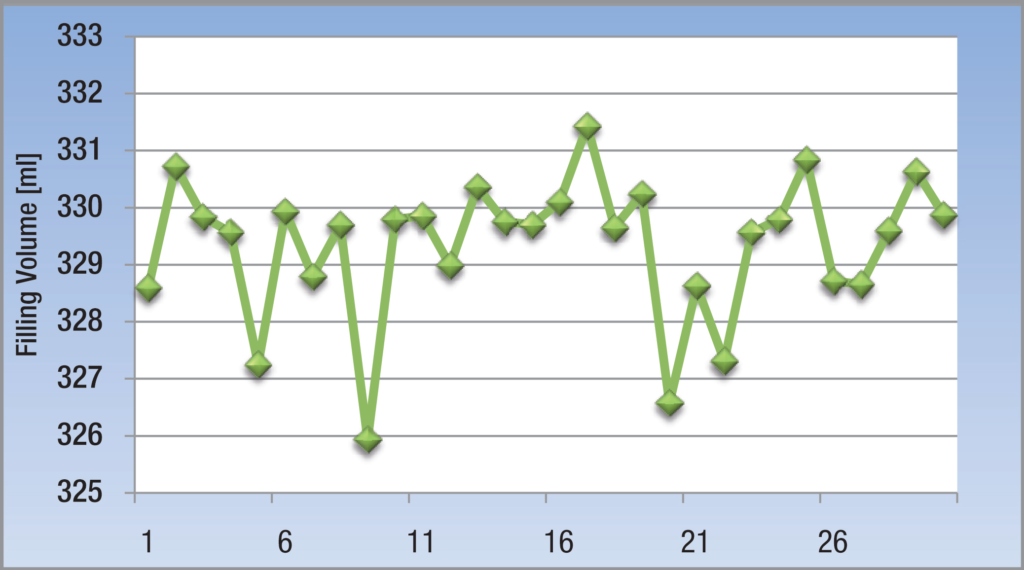

The data that was obtained during the trial was easily put onto a USB stick, and exported to Excel® for further analysis. Figure 1 displays the TPO values over time (n=30). The data for the filling volumes can be seen in figure 2. An average filling volume of 329.34 ± 0.46 ml and a Total Packed Oxygen of 34.9 ± 2.8 ppb as well as an average CO2 content of 4.20 ± 0.07 g/kg prove excellent reproducibility and show strong performance of the bottling equipment and the measurement technology.

Additional Resources

Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

go to HACH.COMIntroduction When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Breaking Down Phosphorus Removal in Wastewater Treatment

go to HACH.COMEfficient phosphorus removal is a complex yet essential process for wastewater treatment facilities that have regulatory requirements. Facing fluctuating influent conditions, operational cost pressures, and regulatory requirements, many facilities...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.