Improving Taste and Odor Issues with TOC Monitoring

Problem

Customers of the Desoto Parish Water Works drinking water facility complained about taste and odor issues in finished water. Organic matter, like bacteria and algae, can be a key contributor to taste and odor in drinking water.

Solution

Desoto Parish installed a Hach® BioTector B3500dw to analyze their water source to identify naturally occurring organics. Additionally, once treated the water is analyzed again to ID any remaining TOC in the water.

Benefit

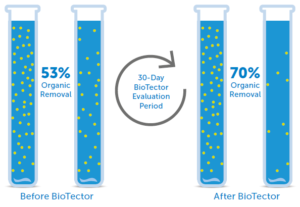

The B3500dw allowed them to measure and track the removal of organics. Increasing removal from 53% to over 70% led to a substantial increase in water quality, improved taste and mitigated odor issues. As a result, customer satisfaction improved.

Improving Taste and Odor

Problem

The Desoto Parish Water Works drinking water facility realized that they had issues controlling the removal of organics after customers complained about taste and odor problems in the finished water. They recognized a need for a Total Organic Carbon (TOC) monitoring solution to identify and allow them to control the TOC levels, while satisfying the Microbial Disinfection Byproduct Rules (DBPR) required by the Environmental Protection Agency (EPA), which outlines process requirements and maximum DBPR contaminate levels.

Solution

Desoto Parish needed a solution to address the customer complaints due to drinking water taste and odor issues. Measuring the naturally-occurring organic materials in the water that vary throughout each day due to the season, temperature, weather, and other compounds in source water were identified as a key opportunity to address these customer issues. Online monitoring is an efficient and effective component in producing the highest quality water possible while maintaining control over coagulant feed and overall treatment and quality control cost.

The BioTector B3500dw is a proven analyzer that identifies man-made and naturally-occurring organics such as TOC by analyzing both raw and finished water used in a drinking water facilities. It calculates and reports EPA required TOC removal and displays results. The analysis of each sample takes only 6.5 minutes. Plan operators see these results as an early warning of water contamination levels. With this early warning, staff can make process adjustments to remain in compliance and maintain quality drinking water.

Microbial Disinfection Byproduct Rules (DBPR)

The Microbial and Disinfection Byproduct Rules help balance the risks from microbial pathogens and disinfection byproducts. The latest revision of the DBP rules requires:

- Water suppliers to evaluate the distribution system, known as Initial Distribution System Evaluation (IDSE), to identify the locations with high disinfection byproduct concentrations to establish sampling sites.

- Water suppliers determine if they have exceeded an operational evaluation level using their compliance monitoring results. The operational evaluation level provides an early warning of possible future MCL violations, which allows the system to take proactive steps to remain in compliance. A system that exceeds an operational evaluation level is required to review their operational practices and submit a report to their state that identifies actions that may be taken to mitigate future high DBP levels, particularly those that may jeopardize their compliance with the DBP MCLs.

The BioTector B3500dw Trial

Desoto Parish installed a B3500dw to analyze raw and finished water up to 200 times per day. Since the raw and finished water facilities were over 300 yards apart, there was no way to test both streams simultaneously. As such, they placed the B3500dw on a bench in the membrane filtration building, located between the raw and finished water structures. Then, at the start of each shift, a five-gallon sample was brought over from the raw and finished waters. The five-gallon sample was enough to see changes in water quality after the chemical feed was adjusted.

After a 30-day-evaluation period, the plant increased its removal of organics from 53% to over 70% percent. This lead to a substantial increase in water quality, eliminated the taste and odor issues, and increased customer satisfaction.

Conclusion

The BioTector B3500dw achieved the following for Desoto Parish Water Works:

- Monitored raw and finished water, and calculated the percent removal, and displayed results every 6.5 minutes.

- Installing a B3500dw allowed Desoto Parish to frequently catch changes that can impact taste and odor in finished water.

- Allowed facility operators to take proactive steps to remain in compliance by means of process adjustments to maintain control, no matter what happens with their incoming water supply.

- Maintained control over coagulant feed and cost.

- Helped Desoto Parish satisfy Microbial Disinfection Byproduct Rules.

- Eliminated the manual collection of TOC data with an analyzer that uses an EPA compliant method, saving highly valuable time and eliminating data errors.

Additional Resources

Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

go to HACH.COMIntroduction When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering...

Maximizing Phosphorus Removal

go to HACH.COMPhosphorus removal plays a critical role in protecting waterways, meeting permit requirements, and managing treatment costs. But optimizing phosphorus treatment isn’t always straightforward, especially when processes, influent conditions, and system...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.