Monitoring Influent Toxicity to Mitigate Risk and Optimize Treatment

Problem

Influent toxicity represents a major risk to the treatment efficiency of biological wastewater treatment plants. If a toxic influent inhibits wastewater biology, this can lead to permit violations, fines, and extended process upsets. Additionally, it will require operator hours and damage public perception of the plant.

Solution

The EZ7900 Toxicity Analyzer, with self-cleaning sample preconditioning panels, provides the ability to continuously monitor toxicity levels at the inlet. It uses real plant sludge, so that dynamic changes in biomass viability are immediately detected, Providing sufficient time for effective mitigation measures.

Benefits

Online monitoring of influent toxicity mitigates risk and helps you stay compliant:

- Improves treatment efficiency and avoids sudden drops in performance

- Avoids downtime and plant failure

- Helps avoid discharge compliance failure

Background

Wastewater treatment plant managers are increasingly being required to accommodate greater capacity, while at the same time complying with tighter discharge permit limits. Consequently, they are under pressure to optimize processes, lower process risks, and improve the quality of treated effluent.

During optimal conditions, a biological wastewater treatment plant has a fast throughput of wastewater with a high rate of removal of organics and nutrients. Sludge settlement is good, with a low rate of sludge production; aeration costs are minimized, and the plant produces high quality final effluent. However, influent toxicity can disrupt normal plant performance, which makes it important to track this non-specific parameter.

If the influent remains consistent, providing sufficient nutrients and at the right level of aeration, the correct balance of microbes will be maintained, and treatment will proceed with optimal efficiency. However, sudden or unexpected changes in the influent have the potential to upset the microbial balance and reduce the efficiency of wastewater treatment. In severe cases, toxic influent can harm the microorganisms to such an extent that the treatment lane would have to be closed, emptied and regenerated.

Historically, influent TOC (Total Organic Carbon, sometimes combined with Total Nitrogen) has been used to predict influent toxicity. However, it is important to note that not all influent changes harm microorganisms. For example, a significant increase in the sugar content of the influent would increase the organic load, but would not necessarily harm the microbes. In contrast, a sudden increase in alcohols coming from a production line, or in cleaning chemicals from a wash-down, would significantly reduce the biological treatment capability of the plant. In these examples, TOC monitoring would indicate an increase in influent TOC, but would not provide any insight into the likely effects on the plant biomass. This is why influent TOC monitoring alone would not provide effective protection from toxic influent.

Safeguarding Activated Sludge Microorganisms

An experienced wastewater treatment plant manager can tell from the appearance and odor of an aeration lane when conditions are not optimized. However, by the time such effects are noticed, it is usually too late – performance has been compromised, and permit limits may have been violated. It is therefore common practice for influent samples to be taken to a laboratory so influent toxicity can be assessed by measuring the respiration rate of those samples.

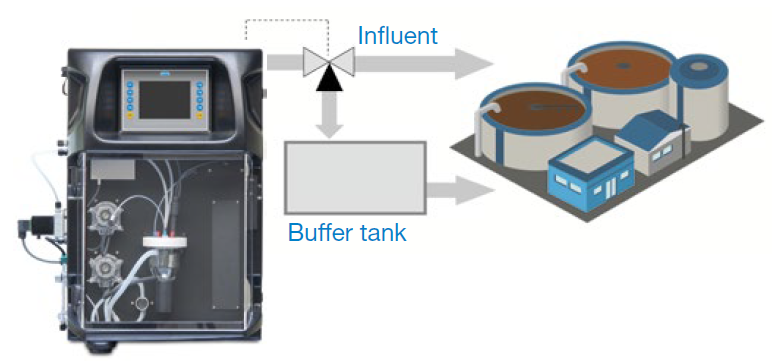

The drawbacks of this manual sampling and analysis approach are that it is costly, time-consuming, and may miss a toxic influent incident, especially if that incident takes place outside of normal laboratory working hours. However, if toxic influent is detected in a timely manner, the plant manager is able to divert the influent to an emergency buffer tank, or to treat or dilute the level of toxicity.

In 2018, Hach® launched an online monitoring technology which is able to detect Influent Toxicity, and provide timely data to the operators of biological wastewater treatment plants; thereby protecting activated sludge, maintaining

treatment efficiency, and avoiding plant downtime and discharge consent failure.

The Benefits of Online Toxicity Monitoring

Risk Reduction

By automating the measurement of influent toxicity, Hach has resolved one of the major risk factors affecting the management of biological wastewater treatment plants. Toxic influent can come from a number of different sources. In a municipal wastewater treatment plant, toxicity may arise from the deliberate or accidental release of toxic waste from an industrial discharge. At an industrial wastewater treatment plant, it may arise from a change in production, a cleaning process, or from a spill or accidental release of harmful chemicals.

By continuously sampling and measuring influent toxicity, the Hach EZ7900 Toxicity Analyzer is able to provide timely warnings so that appropriate mitigation measures can be taken. The cycle time for the instrument is just 10-15 minutes. Many customers typically run at one sample per hour, 24 hours per day, seven days a week. This ensures that all toxicity incidents are detected, night or day.

Process Optimization

By effectively protecting the plant’s biomass from toxicity, online monitoring helps with process optimization; maximizing treatment capacity and helping to optimize the energy and financial costs of aeration. Continuous monitoring also helps to optimize sludge loading, maintain nitrification, and prevent sludge wastage with the effluent.

Process Insights from Plant-Specific Measurements

The Hach EZ7900 automatically collects real sludge, freshly sampled from the treatment plant, by means of a self-cleaning sampling-filtration system. This unique approach, with plant specific sludge, means that data from the analyzer is specific to that treatment plant’s biomass, and dynamic changes in viability are immediately detected.

Potential Sources of Influent Toxicity

- Production-dependent wastewater

- Clean In Place (CIP) processes

- High salt concentrations

- Toxic waste in the collection system

- Increased heavy metal discharges

- Tank truck cleaning station

- Chemical toilet disposal

- Collection system chemical root clean

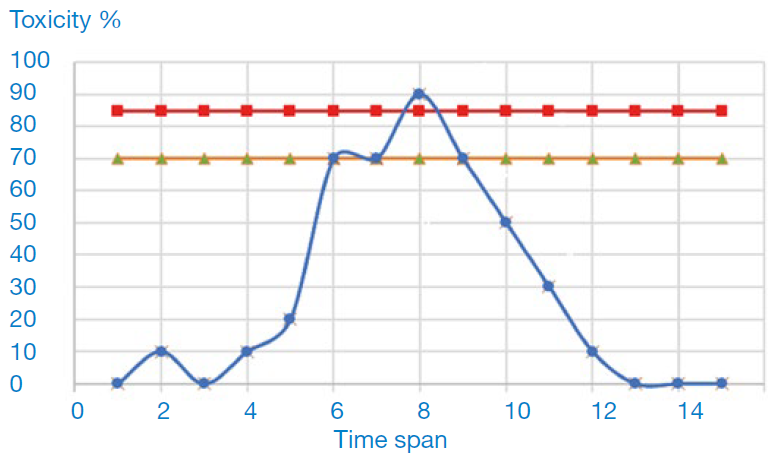

Importantly, continuous toxicity monitoring helps to improve understanding of the plant’s biological processes. For many users, this has provided valuable insights that have been used to refine process control. It is not uncommon for plants to divert influent by rule of thumb when it reaches 50% of the dose that would be lethal to the biomass. However, with the benefit of continuous toxicity monitoring, a number of EZ7900 users have been able to evaluate the effects of higher dose rates, and some have found that it is possible to set the action/divert level as high as 85% for their specific plant. This saves costs and time, improves productivity, and means that less water needs to be diverted and stored.

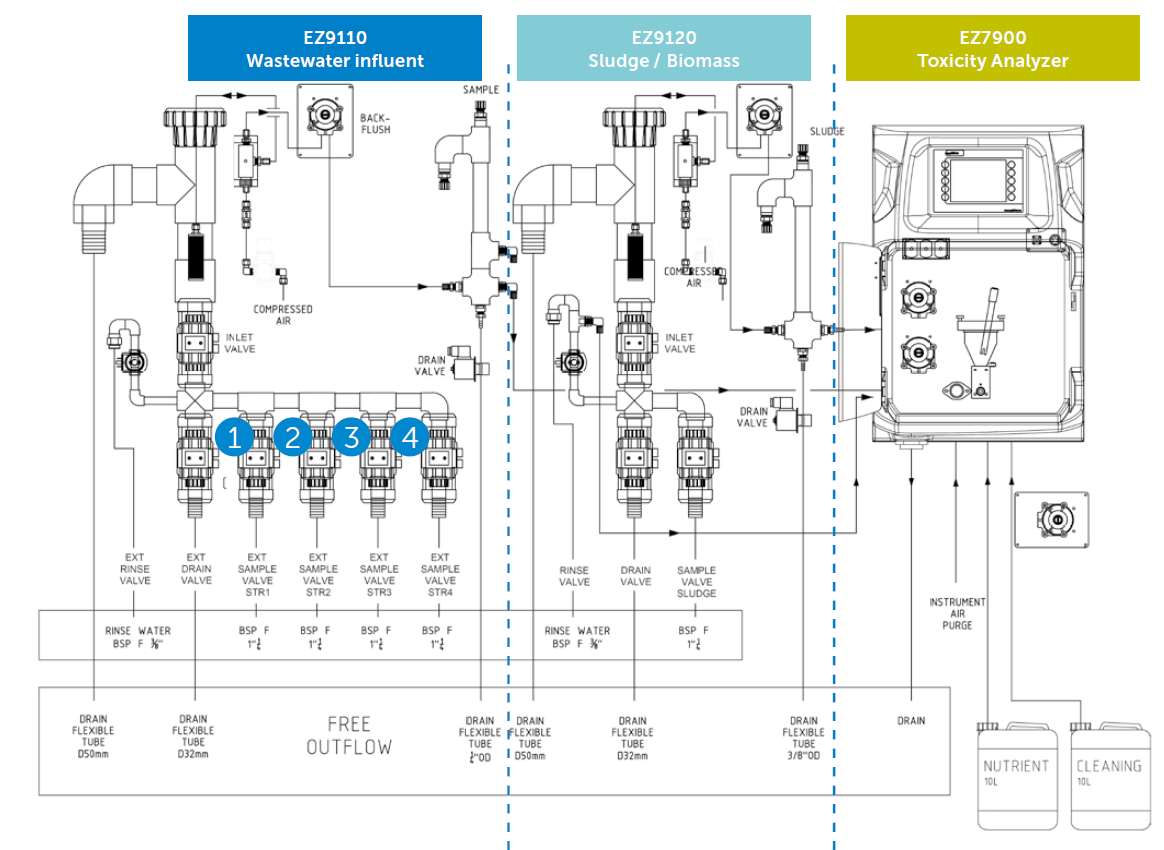

Continuous Monitoring – How It Works

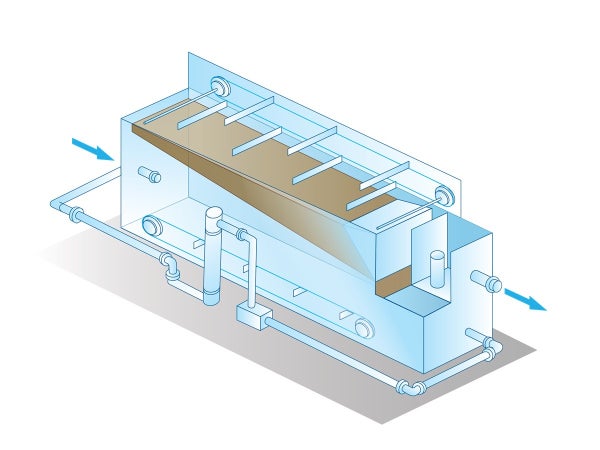

Before analysis, it is first necessary to obtain a representative sample from the influent and a homogeneous sample of sludge from the aeration lanes on the plant. This is achieved with the EZ9110/9120 Series automatic sampling and sample preconditioning systems, which have been developed with many years of field experience. These preconditioning systems use pressurized air and rinse water for self-cleaning, and are designed for fully automatic, unsupervised operation.

The EZ7900 Toxicity Analyzer incorporates an industrial panel PC running proprietary controller software, and a 5.7” TFT color user interface for on-site data visibility. The software allows for modification of visibility and analysis settings and visualization of data trends. It controls the operation of up to eight influent sample streams in a single analyzer, with results for each stream communicated through individual outputs such as mA or Modbus. This multi-channel capability dramatically reduces the cost per sampling point, and a standard 4-20 mA signal output with alarm processing can be established for each channel, so that appropriate and timely action can be implemented.

The cleaning of the filters and the analyzer is automatic, and both calibration and validation frequency can be set by the user. Smart, automated features contribute to enhanced analytical performance, minimized downtime, and negligible operator intervention. Nevertheless, Hach offers a range of Service Agreements to ensure continuous, reliable, hassle-free operation.

EZ7900 Analyzer: Method Overview

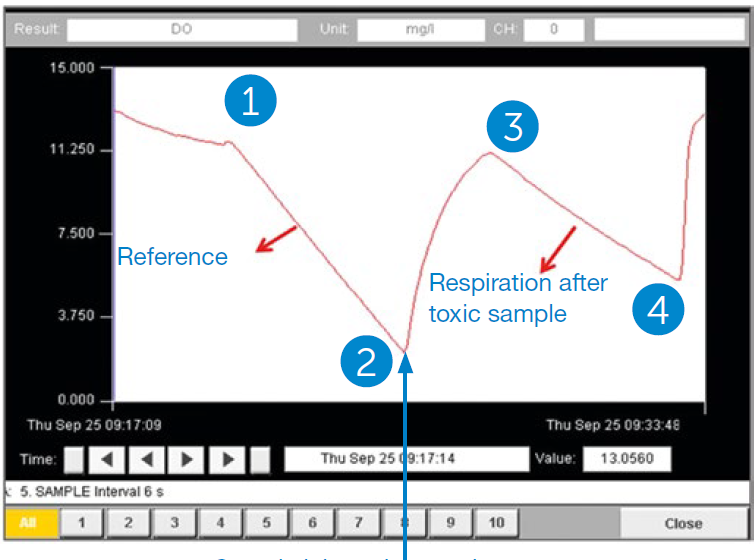

Calculation #1 (Reference Value)

Respiration Rate REF = (Oxygen 1 – Oxygen 2) / Time

Calculation #2 (Toxic Respiration Rate)

Respiration Rate TOX = (Oxygen 3 – Oxygen 4) / Time

Calculation #3 (Final Result)

Toxicity Index (% Inhibition) = R.R. TOX / R.R. REF

Reference Measurement

- Activated sludge and influent wastewater are auto-filtered

- Analyzer aerates sludge and adds nutrient buffer

- Aeration stops and O2 consumption in sludge is measured

- Respiration rate for “healthy” sludge is calculated

Toxicity Measurement

- Wastewater influent added to vessel and aerated

- Aeration stops, nutrient buffer is added, and second O2 consumption value is measured

- Respiration rate for wastewater sample is calculated

- Calculation of respiration rate and toxicity index

- Filters, analyzer, and O2 probe are auto flushed and rinsed

Summary

The health status of the biomass in a biological wastewater treatment plant is vital to the ongoing efficiency of the entire plant, so it is vital to be able to detect both chronic and acute influent toxicity with sufficient time to implement effective mitigation measures (divert, dilute or treat).

Manual sampling may mean that some toxicity episodes are missed, or alarms are issued too late. Online methods that do not use the plant’s own biomass to measure the oxygen update rate (OUR) of microbial respiration will also be of limited value, as artificial biomass is not representative of actual plant conditions.

By utilizing the plant’s own biomass, and by automating the process to enable 24/7 monitoring, the Hach EZ7900 offers the ideal solution for mitigating the risk presented by toxic influent, while also providing insights for process control, improving performance, and avoiding discharge consent failure.

| Aspect | Manual Sampling | EZ7900 Online Monitoring |

|---|---|---|

| Detection Speed | Delayed, results depend on lab turnaround (hours to days) | Near real-time, cycle time 10–15 minutes |

| Operator Effort | Manual collection, transport, and lab analysis required | Fully automated, self-cleaning, minimal operator intervention |

| Reliability | May miss toxic events, especially outside lab hours | 24/7 monitoring ensures all incidents detected |

| Plant Specificity | Relies on lab surrogates, not always plant-specific | Uses actual plant biomass for accurate, site-specific insights |

Key Outcome: Real-time toxicity detection with the Hach EZ7900 protects biomass, prevents compliance failures, and provides actionable insights to optimize treatment performance.

Additional Resources

Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

go to HACH.COMIntroduction When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering...

Maximizing Phosphorus Removal

go to HACH.COMPhosphorus removal plays a critical role in protecting waterways, meeting permit requirements, and managing treatment costs. But optimizing phosphorus treatment isn’t always straightforward, especially when processes, influent conditions, and system...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.