Oil and Gas and Refineries TOC Management

The Management Tool with Operational and Commercial Impact

TOC Sampling and Measurement Challenges

The Hach® BioTector B7000 is a management tool with unique technology. It supplies reliable and accurate TOC (total organic carbon) data for incident response and production efficiencies. BioTector Online TOC Analyzers are used by many of the largest oil and gas companies globally.

Oil is a hydrocarbon with a very high concentration of TOC. If there is an oil breakthrough in the processing environment, things can become serious rapidly. It is imperative that plant operations have real-time, accurate, and reliable information regarding TOC levels in the process water and wastewater. This information gives visibility of any breach in the process lines which enables the operations team to respond rapidly, thus reducing risks to the plant and environment. BioTector data also improves overall process control and is often an integral part of clients’ continuous improvement programs.

Attaining high levels of accuracy and reliability in this industry can be difficult for many Online TOC technologies. TOC spikes in the wastewater can dramatically affect an analyzer and cause problems including contamination or blockage of the sample tubes, slow recovery or analyzer downtime, and significant maintenance requirements. BioTector patented technology overcomes these issues.

Unique Technology, Engineered for Reliability

The Hach BioTector B7000 has successfully operated in the oil and gas industry since 1996 and is widely acknowledged to be a robust analyzer capable of withstanding the challenges typical of this industry.

Industry trials and tests, such as the U.S. Instrumentation Testing Association Field Test 2011, demonstrate the superior, reliable performance of BioTector patented Two Stage Advanced Oxidation (TSAO) technology in a harsh petrochemical processing environment. Other technologies such as UV Persulfate and High Temperature Oxidation demonstrated ongoing maintenance issues in these same conditions.

BioTector was awarded the Frost & Sullivan U.S. Product Leadership Award in 2012 and the Frost & Sullivan report stated:

“BioTector analyzers are strong enough to survive in acerbic industrial environments… BioTector is a market leader with an estimated 25–30% share of the U.S. TOC water and wastewater analytical instrumentation market.”

A significant portion of the BioTector U.S. installations are in the oil and gas industry.

Application Types

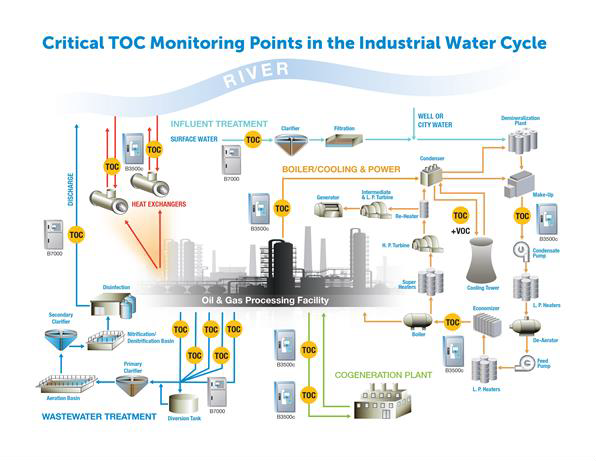

Typical TOC Monitoring Points for the Oil and Gas Industry

| B7000 Applications | B3500c Applications |

|---|---|

| Influent to the WWTP | Condensate Water |

| Effluent from the WWTP | Cooling Water |

| API Separator | |

| River Water Monitoring | |

| Desalination Plant |

Diagram of Typical Plant

Hazardous Areas

Hach BioTector B7000: Four Options for Hazardous Areas

| Class 1, Div 1 | ATEX Zone 1 |

| Class 1, Div 2 | ATEX Zone 2 |

Operational Efficiencies Delivered by BioTector

| BioTector TSAO Technology | Operational Benefits |

|---|---|

| Real-time Visibility of Oil present in the Wastewater | Management and operators can make decisions on water reuse, diversion strategies, production processes and wastewater treatment plant (WWTP) operations, etc. |

| Low Maintenance Requirements | No increase to your head count. No burden on your existing maintenance team. Routine service and calibration only required twice each year. |

| Self-Cleaning Technology | Each part of the analyzer that comes in contact with the sample is cleaned after every measurement cycle. BioTector is the only analyzer capable of multi-streaming without risk of sample contamination or carry over. |

| Reliability | Outstanding field performance, MCERTS certified uptime of 99.86%. |

| No Filtration Required | Representative samples = Accurate data. |

| Rapid Recovery from TOC spikes | Continuous analysis even in difficult and fluctuating applications. |

| Alerts and Alarms | Rapid incident response and enhanced process control. |

| Remote and Networkable Access | Multi-analyzer information at-a-glance and a further decreased workload for your on-site maintenance team. |

Commercial Value of BioTector Management Information

The oil and gas industry is focused on reducing the cost of operations while simultaneously increasing operational efficiency. BioTector TOC analyzers offer intelligent surveillance of wastewater loading which can enable the Operations team to make significant improvements throughout the plant. Clients have reported the commercial value of BioTector in four key areas:

1. Energy Optimisation

Aeration can be up to 30% of the annual budget for a WWTP so the ability to optimize this via accurate BioTector measurements is highly valuable. TOC levels in wastewater influence the level of aeration required. High TOC levels require increased aeration blower activity to treat the wastewater, low TOC levels can be treated with lower aeration activity.

2. Water Reuse

In a situation where TOC information is unreliable, operations personnel are often compelled to expel all used water after one circulation rather than run the risk of damaging equipment. This preventative measure is extremely expensive. Accurate visibility of water allows for more cost-effective usage.

Water often comes in to the plant from the local river; it travels through heat exchangers and circulates around the plant. TOC levels in this water are monitored at various points in the process as a means to identify any oil breakthrough that could cause damage to plant equipment. If this occurs, contaminated water is diverted to the drain and the source of the leak is identified. Alternatively, if TOC levels are verified to be within acceptable limits, the water will be reused.

3. Maintenance

Industry reports highlight that skilled resources are in decline; an Ernest & Young survey stated that 22% of oil and gas companies indicate that a lack of qualified personnel impacts operations. BioTector was designed and engineered to maximize reliability and to minimize maintenance in the field.

The value of this low maintenance analyzer is that it allows on-site personnel to focus on their core business – not tying them up in support of problematic analyzers.

4. Protection

Reliable TOC monitoring is effective in the protection of valuable equipment; the WWTP and ultimately of the production function. TOC data can be used to ensure that:

- Recycled water is safe (i.e., non-corrosive and can be used with expensive equipment)

- Wastewater loading and capacity levels at the WWTP are compatible

- Production will not be disrupted or halted due to damage caused by breakthrough

Measuring VOCs

BioTector also has the unique capability to include and specifically measure the amount of VOCs (volatile organic carbons) in a sample – this is essential for some plants and is particularly important in API separators. As the wastewater passes through the system it has the potential to vent VOCs. In many cases the refinery will completely enclose the API with a vapor recovery system and burn the VOCs in a flare. In other cases, the API is open and the refinery needs to monitor the VOCs for air permit reasons and to regulate odor.

B3500c For Clean Water Applications

Hach BioTector B3500c uses the same powerful TSAO technology as the B7000 but comes with a smaller footprint and price tag as it is designed for clean water and condensate applications only. Crude oil refinement is very energy intensive with a high requirement for steam and hot water during processing. Hot condensate contains a lot of energy and is very valuable to the plant. Significant cost savings can be made through re-using return condensate or steam condensate. However, the purity of this condensate water is of vital importance so that equipment is not damaged via corrosion. The condensate needs to be monitored with utmost accuracy and stability. In refineries, the alarm thresholds are typically 50-1,000ppb.

Clients include: Chevron, E.ON, Exxon, GS Caltex, Hexis, Motiva, Natref, OMV Refining, Ormen Lange, Petroleum Company of Trinidad, Petronas, Praxair, SABIC, Sasol, Shell, SKC, SK Energy, S-Oil, Statoil, Syndial, Total Refinery, Valero, Valmax, YPF…

Call your local Hach BioTector representative for more details on how BioTector can impact your organization.

Additional Resources

Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

go to HACH.COMIntroduction When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Breaking Down Phosphorus Removal in Wastewater Treatment

go to HACH.COMEfficient phosphorus removal is a complex yet essential process for wastewater treatment facilities that have regulatory requirements. Facing fluctuating influent conditions, operational cost pressures, and regulatory requirements, many facilities...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.