Optimization of Dechlorination and CIP Processes for RO Filtration in the Power Industry

Process Overview

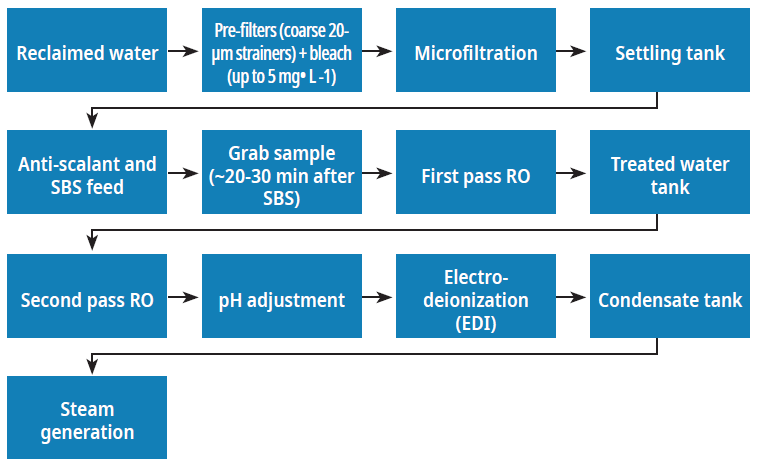

A power generation station in California uses reclaimed source water and chlorinates/dechlorinates it prior to RO filtration to produce water for the steam generation cycle. No other biocides are used at this station. The utility personnel mainly rely on grab sample analysis for monitoring chlorine residual before and after antiscalant and Sodium Bisulfite (SBS) addition in the 1st pass RO feed. The schematic in Figure 1 depicts the water treatment cycle implemented at this facility.

Problem

The RO membranes are routinely cleaned using a “Clean-in-Place” (CIP) process, the frequency of which varies based on the season and the consistency of chlorine presence in the water. The utility targets 0.02–0.08 mg/L total chlorine residual in RO feedwater, and it is challenging to achieve this goal while minimizing CIP frequency. As a result of inadequate monitoring, chlorine excess in the RO feed sometimes leads to unscheduled and costly membrane replacements. It is imperative to have no chlorine post-RO, especially for the 2nd pass RO and the electrodeionization (EDI) system intolerant of any chlorine presence, hence the need for accurate chlorine monitoring. Potential losses related to insufficient process control comprise the direct cost of the membranes (RO and EDI) and CIP process (chemicals and downtime), as well as the indirect cost of lost energy production. Therefore, reducing CIP frequency was one of the main cost saving objectives for this study.

Solution

The utility tried ULR CL17sc process analyzer to measure chlorine residual in the pre-RO (1st pass) water after SBS addition. The main goals of this test were to see whether the analyzer can significantly limit the risk of chlorine breakthrough while lowering operating costs through more efficient dechlorination process control. One of the biggest challenges for any process analyzer would be the intermittent sample flow, which was the case for the operation of the RO system as it is implemented at the facility.

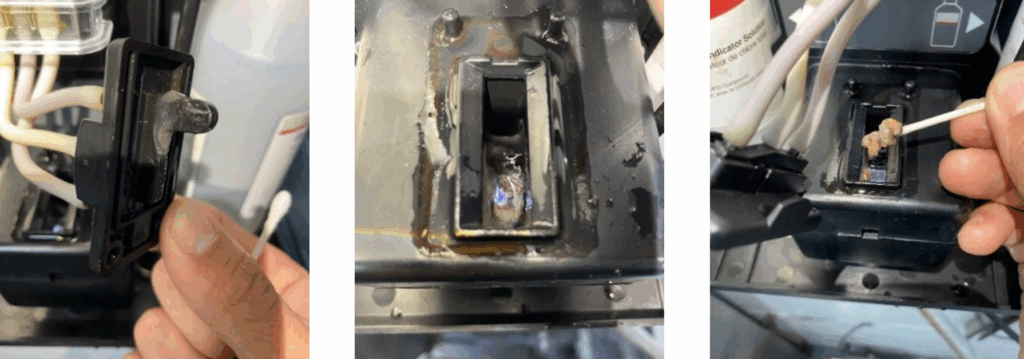

Another significant challenge was the inevitable biofouling of the internal hardware, due to the frequent absence of chlorine at excessive feed of SBS. Fouling of the analyzer reflects potential fouling of the membranes, which is mitigated by CIP. One of the test’s secondary objectives was to define the optimal maintenance interval to prevent a negative effect of biofouling and to evaluate the effort and requirements for cleaning. During the test at this power station, it was discovered that the fouling started interfering with the measurements after about 4 months of operation. Regular monthly cleaning with the provided maintenance kit (Figure 2) helped to remove it in 3-5 minutes when replacing the reagents. The information logged by the instrument during the test enabled important conclusions about the analyzer’s abilities and the accuracy of the results. For example, the analysis of the sample flow recorded by the instrument, in conjunction with the chlorine readings and other events registered in the internal logs, allowed the conclusion that intermittent operation of the plant did not adversely affect the results. Such conclusions led to acceptance of the instrument by the personnel and decision to connect the analyzer’s outputs to the station’s DCS (distributed control system).

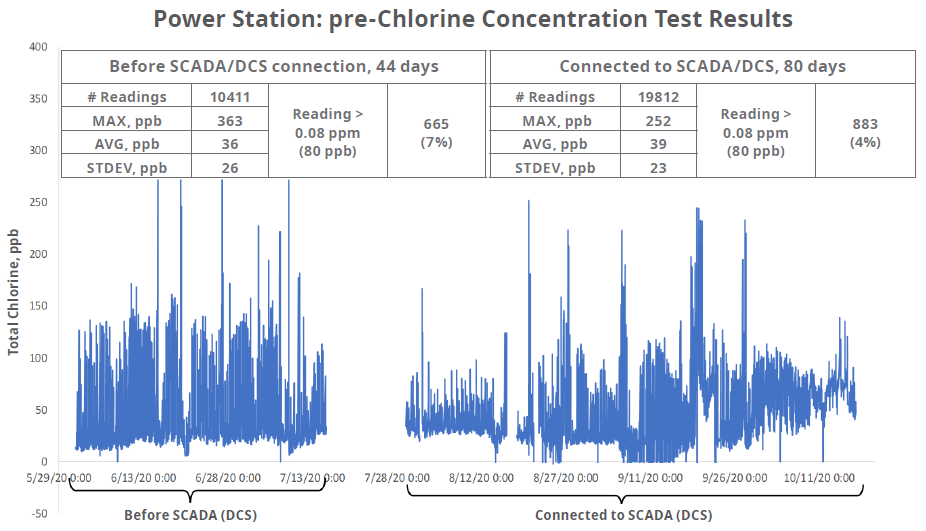

The data presented in Figure 3 show the chlorine readings before and after connecting the analyzer to the DCS, which happened once the analyzer was accepted for decision support, if not for control of the dechlorination process. Once the readings became visible to the operators, the process control improved, as reflected in the number of daily chlorine excursions exceeding the critical level of 0.08 mg/L (80 ppb) set by the plant, which was reduced to 11 vs. 15, or 4% (after) vs. 7% (before). By better control of chlorine residual the station was able to reduce SBS feed without compromising on biofouling control, which led to chemical cost saving and reduced frequency of the CIP, which provided additional significant cost savings.

The test at this facility lasted over a year with the analyzer being exposed to various and challenging conditions. The long-term test data analysis showed a chlorine breakthrough event registered by the instrument, which had provided warnings about ten days earlier, as well as produced a high chlorine alarm immediately before the event. The event was, unfortunately, overlooked and the rising chlorine concentrations post-RO eventually affected the deionization process, as was detected by the falling resistivity of the EDI effluent water. The latter helped to discover the breakthrough, and the operators increased bisulfite feed, which eventually brought the process under control. According to the plant representatives, this situation indicated an inevitable learning curve in accepting the new instrumentation and utilizing its readings for process optimization.

Outcomes

During the trial, improved management of the chlorination/dechlorination process resulted in a more than 30% reduction in SBS usage and halved the number of CIP cycles due to a significant reduction in membrane biofouling because of a better and more tightly controlled chlorine residual.

The reduction in the frequency of RO cleaning and maintenance provided regular cost savings, as the plant contracts temporary RO trailers to be brought on site to provide needed capacity while their primary system is offline. After the testing, the facility planned to order another ULR chlorine analyzer and install it before the 2nd pass RO membranes. This would provide a trigger associated to a (high-high) chlorine alarm to further protect their EDI and the power generation cycle.

These are tangible benefits that justify all the costs associated with the analyzer, consumables, and maintenance. With higher acceptance of the instrument and its features, such as the Cumulative Chlorine Counter™, the process optimization at this facility is also projected to reduce losses in power production and increase the useful life of the RO membranes, providing further cost savings.

Conclusion

The test at this facility lasted over a year with the analyzer exposed to challenging conditions. The long-term test data showed that the analyzer was able to provide early warnings for chlorine breakthrough events and trigger alarms before they impacted downstream processes. Although one event was overlooked, operators adjusted SBS feed and brought the process under control. The adoption of the ULR CL17sc analyzer improved process control, reduced SBS usage, lowered CIP frequency, and extended membrane life, ultimately contributing to reduced costs and higher operational reliability.

Key Outcome: Improved process control delivered a 30% reduction in SBS usage and 50% fewer CIP cycles, significantly lowering chemical and maintenance costs while extending RO membrane life.

Additional Resources

Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

go to HACH.COMIntroduction When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Breaking Down Phosphorus Removal in Wastewater Treatment

go to HACH.COMEfficient phosphorus removal is a complex yet essential process for wastewater treatment facilities that have regulatory requirements. Facing fluctuating influent conditions, operational cost pressures, and regulatory requirements, many facilities...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.