Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

Introduction

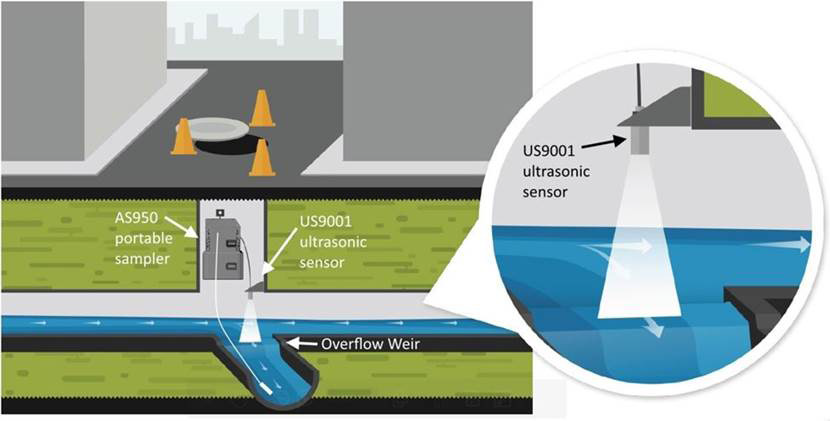

When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering the start or end of sampling programs with setpoint conditions. The flow sensors that the AS950 is compatible with are the US9001 down looking ultrasonic sensor1, and the submerged pressure area velocity (sub-AV) sensor.

Benefits of digital flow sensors:

- Collect samples that better represent your flow stream with the ability to automatically adjust the volume per sample or the interval between samples proportionally to flow.

- Start sample programs based on flow parameter setpoints like high level or flow.

- One instrument in a compact package – ideal for tight installation locations like manholes.

- One power source – one battery or one power supply.

- Lower cost to purchase compared to separate flow and sampler instruments.

- All your data in one file – sample data and flow data together for streamlined report generation.

Application scenarios

To select the best flow sensor for the application, we need to know some specifics about the installation location.

Flow can be broken down into two categories: closed pipe (pressurized), and open channel (free flowing, gravity driven).

Hach offers sensors for open channel flow (we can sample from both). The open channel category can be broken down into

three sub-categories: hydraulic structure (flumes and weirs), mathematical (Manning’s Equation), and area velocity (AV).

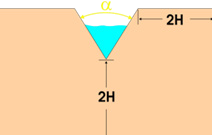

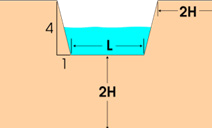

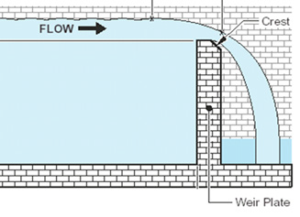

Weirs

A known head (depth) to discharge relationship has been determined for each weir geometry and therefore only the measurement of the head above the crest needs be collected to determine flow.

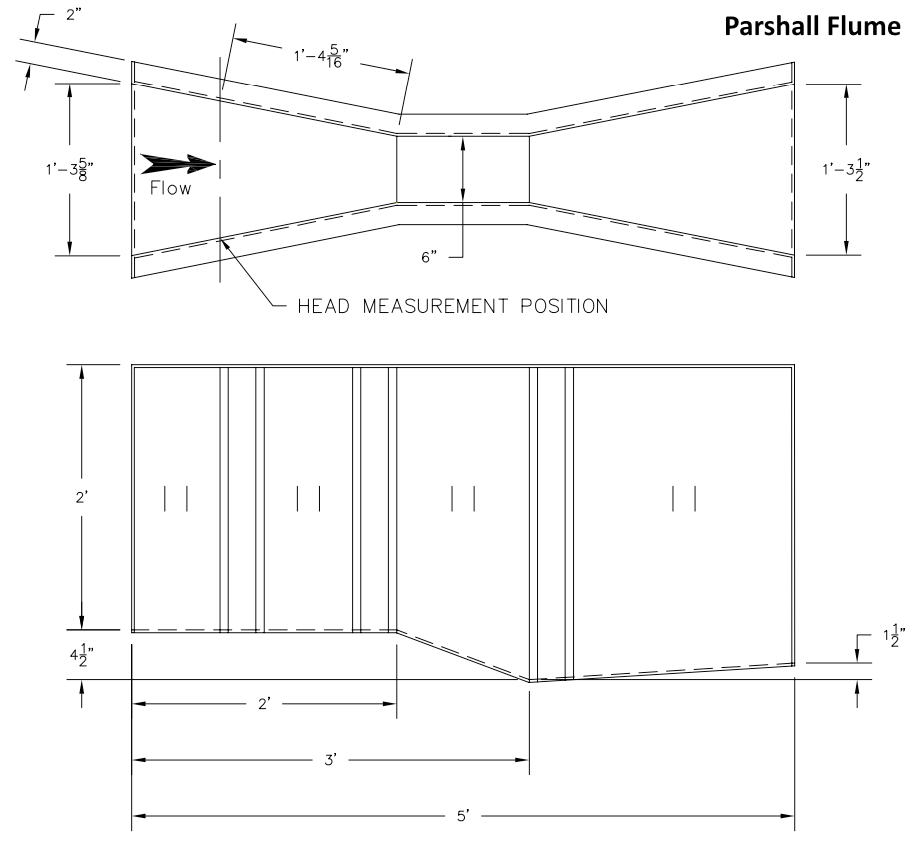

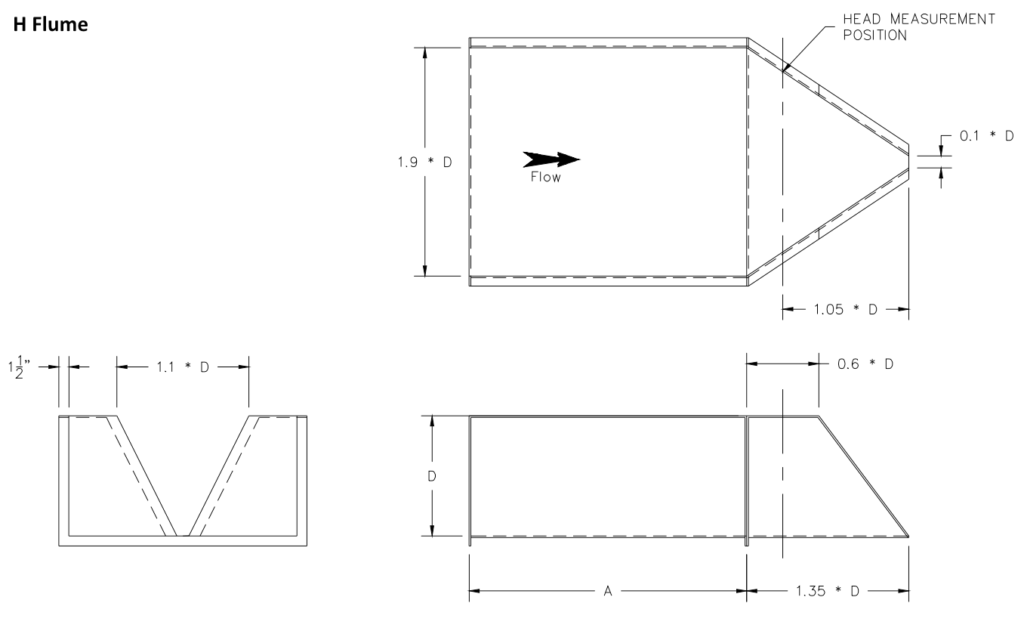

Flumes

A known head (depth) to discharge relationship has been determined for each flume type and size, and therefore only the

measurement of the head in the appropriate location needs to be collected to determine flow.

Manning’s Equation

- The Manning Equation is a method of estimating flow rates in open channel flow applications that exhibit good hydraulic characteristics (laminar flow) and where surcharge is not likely.

- Flow rates are calculated using a level input to determine wetted area.

- Slope and the “roughness coefficient” are constants specific to each application.

Manning’s equation: Flow = (1.0/N) × (A5/3 S1/2) / P2/3.

Key

Flow = flow rate

A = cross sectional area

P = perimeter

N = roughness coefficient

S = slope

Best sensor for flumes, weirs, and Manning’s Equation

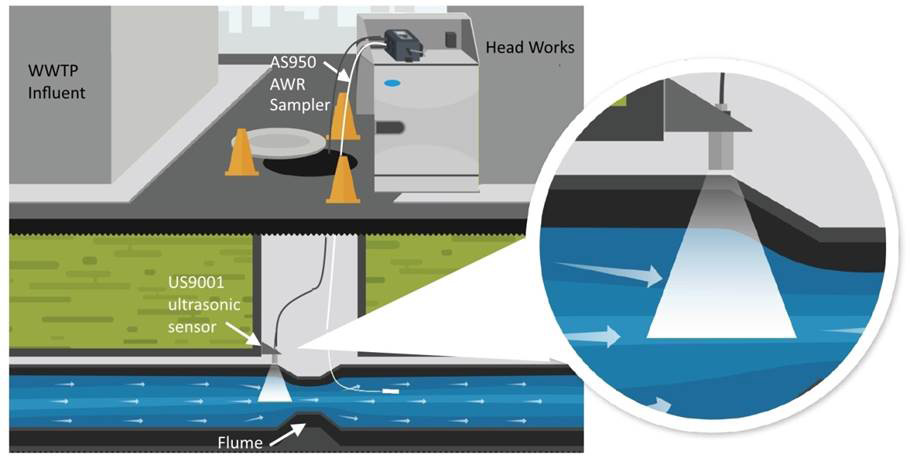

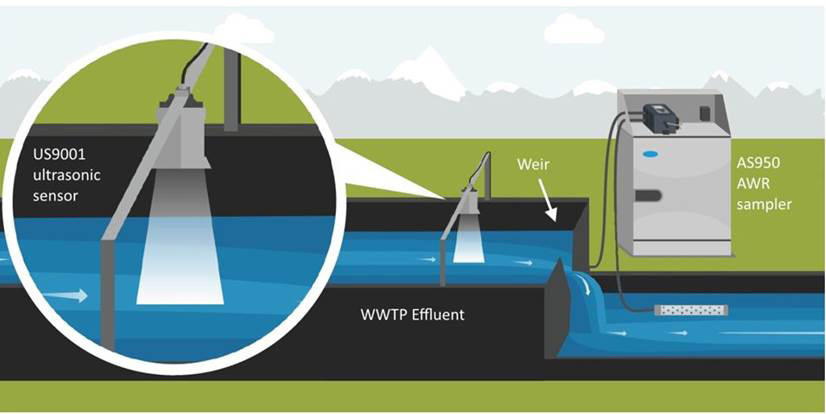

The Hach US9001 down looking ultrasonic sensor includes:

- A non-contacting sensor; which means no sensor fouling and reduced maintenance.

- Zero-drift ultrasonic technology.

- A LED status indicator that confirms proper operation.

It is common to find a flume at the influent to a treatment plant. The US9001 ultrasonic sensor is perfectly suited for these applications:

A weir is often present at the effluent. The US9001 ultrasonic sensor is ideal for these applications:

Overflow weirs are another suitable application for the US9001:

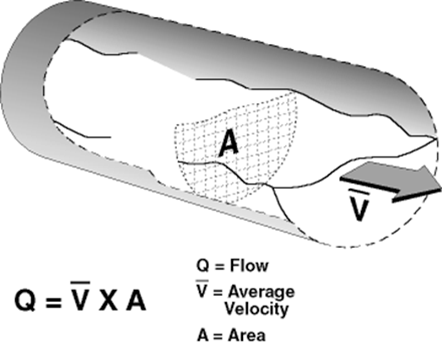

Area velocity

- When no hydraulic structure (weir or flume) is present, site hydraulics are less than optimal, and/or the possibility of surcharge exists, area velocity (AV) is the preferred method of flow measurement.

- The Continuity Equation simply stated is:

- Flow Rate = wetted area x average velocity

Best sensor for area velocity

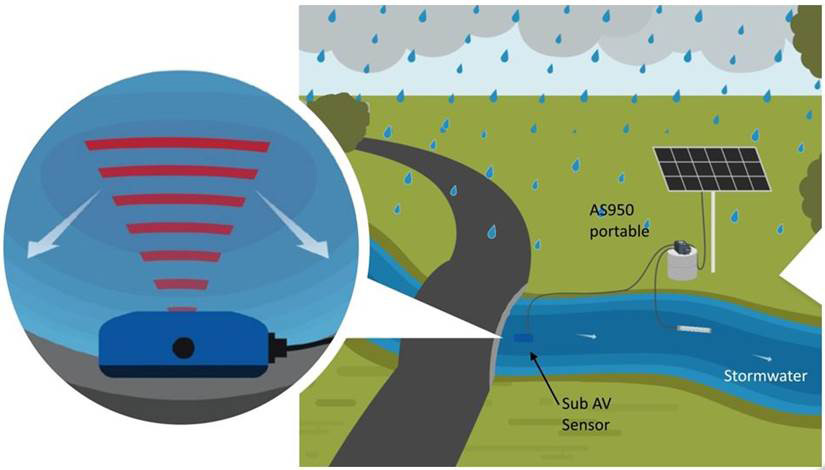

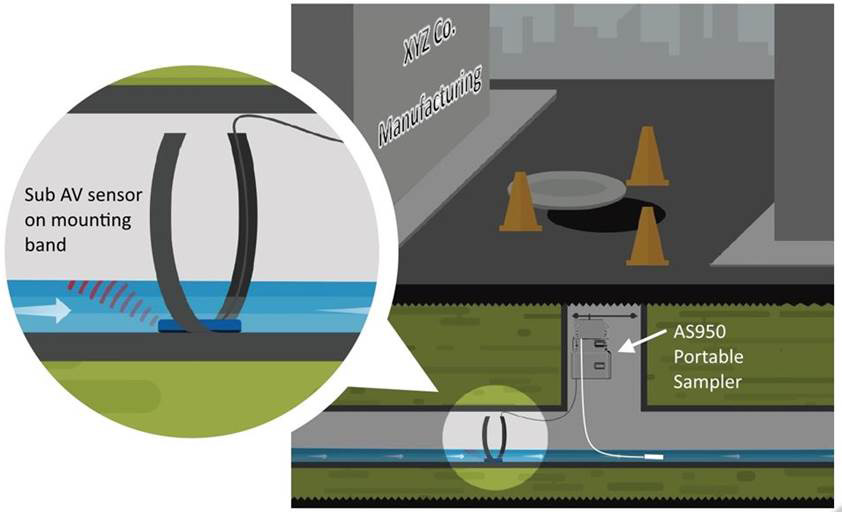

The Hach AV9000/Sub AV sensor:

- Has a proven accurate and reliable area velocity method.

- Can verify that the sensor is performing accurately before you leave the site.

- Has bi-directional velocity.

- Includes advanced digital signal processing, providing great performance in difficult hydraulics.

A sub AV sensor installed in a dry stormwater drainage culvert signals the sampler to take a sample during a storm and paces the sampler for flow proportional samples

Measuring the effluent flow at an industrial site helps determine loading for comparison to NPDES permit limits

How to order

To properly configure your Hach AS950 for flow, you will need the sensor port option, flow sensor, and sensor mounting hardware. Please contact your local salesperson for more information or explore our AS950 portable sampler products on Hach.com.

- US9001B ballast and US9003 in-pipe also available ↩

Additional Resources

Maximizing Phosphorus Removal

go to HACH.COMPhosphorus removal plays a critical role in protecting waterways, meeting permit requirements, and managing treatment costs. But optimizing phosphorus treatment isn’t always straightforward, especially when processes, influent conditions, and system...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Breaking Down Phosphorus Removal in Wastewater Treatment

go to HACH.COMEfficient phosphorus removal is a complex yet essential process for wastewater treatment facilities that have regulatory requirements. Facing fluctuating influent conditions, operational cost pressures, and regulatory requirements, many facilities...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.