Quality Control in the Brewery: Reference Standard for TPO Analytical Methods

The quest for a TPO (Total Package Oxygen) reference standard is still open, despite the wide use of methods and devices measuring this important parameter in the brewery. Today TPO is one of the unique parameters in the beer analyst’s toolbox that has no standard. Below, a new method to build a TPO standard is described and compared with other methods. This new standard is then used to evaluate the TPO measurement through existing methods.

Oxygen is considered a critical parameter affecting the freshness profile of packaged beer.

In 1984 K. Uhlig and C. Vilachá, published a paper that was a breakthrough for several reasons:

- Moving from air to oxygen measurement

- Moving from wet chemistry to analysis with modern instrumentation

- Improvement in the low detection limit to a few ppb’s, when previously it was about only 1ml air (corresponding to 270 ppb TPO)

25 years later, another major step was reached when instrumentation manufacturers’ invented Analysers specially dedicated to TPO.

Among all methods, the air injection was identified to provide the best results. The strength of this method was demonstrated in combination with the new Orbisphere 6110 Analyzer from Hach®.

What is TPO?

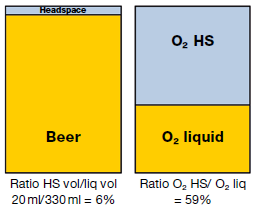

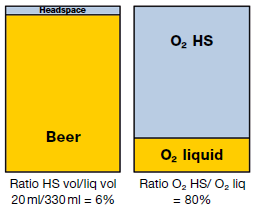

Figure 1 shows a 330 ml can at 8°C after equilibration and Fig. 2 shows an example of a can straight after the filling. Yellow and blue areas show the beer and headspace volume with the associated O2 content. Calculation for Fig. 1 was made with the Z factor. The proportion of each surface matches the ratio of volume and oxygen content.

The TPO paradox is that the main location of the oxygen in the package is in the smallest volume: the headspace.

At first, physical properties of oxygen explain this phenomenon. Being 30 times less soluble than CO2, the oxygen will remain in gas phase, with a concentration according to the temperature of the liquid and volumes ratios. This is shown in Fig. 1.

Any HS vol variation has also an important impact on TPO, a 10 ml headspace volume increase generates a TPO increase of 9%.

Requirements for a TPO standard

Identifying the fitness for purpose of a new TPO standard reference was evaluated by the following set of criteria:

- Precision (trueness)

- Repeatability

- Reproducibility

- Range

Easiness of implementation (can be deployed everywhere, lab and plant floor; not operator dependent)

Principles of evaluated TPO standards

The main goal for the TPO standard is to have a known amount of oxygen in a package with a known uncertainty.

Many potential methods are based on the introduction of an unknown or known amount of air into the package HS. In chemical analysis this method is also called SAM (Standard Addition Method).

Prior to the air injection, a batch of blanks (old beers with low oxygen) is analysed. The expected final value is the sum of the blank TPO concentration and the added air.

Potential solutions for TPO standards

Headspace flushed with air

Bottles are prepared in a cabinet with an oxygen controlled atmosphere.

This method shows good trueness and repeatability but the method requires special devices and long flushing times. This has a negative consequence on the easiness of implementation.

Water test cans

A batch of carbonated water cans is taken from a filler with known performances, in regards of the air pick-up. A part of the batch is measured and the statistical TPO distribution identified.

This is an easy method to implement, but trueness cannot be identified.

This method was initially evaluated by the ASBC in 2004 and then rejected.

Air injection into the foam of open bottles

A bottle of pasteurised beer is carefully uncapped. The side of the bottle is gently tapped with a solid rod to induce a large amount of foam escaping the top of the bottle. A syringe of air is inserted into the foam and the contents injected. A crown is immediately replaced on top of the bottle and sealed.

This method was also evaluated by an ASBC subcommittee and rejected in 2007 after an inter-laboratory test. Repeatability and differences between collaborators were estimated to be not good enough.

Air injection in the HS

This is a variant of the initial ASBC method described previously. In this method the crown cap is changed with a different one which includes a septa. This method gave a repeatability and reproducibility found with a ratio std dev/average of 28%. A specific crown cap needs to be prepared specially. Trueness of 80% was found with the standard TPO analysis method which means a 20% error.

The new method: Air injection in cans

A variant of this method was mentioned by the ASBC subcommittee in the conclusion of their final report in 2007. A known amount of air is injected into an aluminium can where a rubber septa is previously stuck at the point of injection, the septa is maintained in his location with a large hose clamp. See Fig. 3.

After 4 years of use, this method has provided good results.

The sample preparation is easy and this method allows the injection of almost any amount of air in the can. It therefore provides a solution for trueness, linearity and repeatability.

Standard cans of old beer are used and the time required for the preparation and easiness of implementation are acceptable.

Methods evaluation

Table shows an evaluation of all methods across different criteria.

| Criteria | Water test cans | Air flush in HS | Air injection in foam | Air injection in HS | Air injection in cans |

|---|---|---|---|---|---|

| Precision (trueness) | ◔ | ◑ | ● | ● | ● |

| Repeatability | ◑ | ◑ | ● | ● | ● |

| Reproducibility | ◑ | ◔ | ● | ◑ | ● |

| Range | ◌ | ◔ | ● | ● | ● |

| Easiness of implementation | ● | ◌ | ◑ | ◑ | ◕ |

Air injection method applied to the Orbisphere 6110 TPO Analyzer

The Orbisphere 6110, measures O2, CO2 and HS volumes with the gas content in both the HS and the liquid. The system uses a patented gas sampling technique. See Fig. 4.

The repeatability of samples measured after the air injection with one Analyzer, the same operator, and at 170 ppb average, was found between ±20 ppb down to ±2 ppb, this last value obtained with skilled operators.

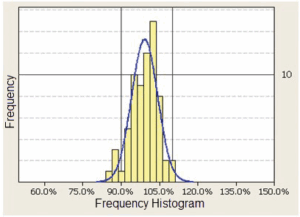

The recovery ratio parameter is used as a standard validation routine. Recovery is the ratio (O2 measured)/(O2 injected) and ideally should be 100%. See Fig. 5.

The complete measurement process is automatic and the absence of contact between sensors and the liquid minimises maintenance requirements and ensures consistent operation and results reliability.

The average recovery found was excellent, at 99.2% (159 ppb) and with a standard deviation of only ±5 %.

For a confidence interval of 95%, measurements were found between 144 ppb and 176 ppb.

Linearity validation is often done during commissioning. An example is shown on Fig. 6 with a coefficient of determination R2 at 0.99 demonstrating the excellent linearity of the air injection method and the Analyzer.

![TPO linearity 440 ml cans chart showing measured TPO [ppb]](/wp-content/uploads/2025/10/qc-in-brewery-measured-tpo-300x203.png)

Benefits of the new TPO reference

Data from collaborative tests are not available yet but hundreds of air injections performed on different sites have shown that this method provides a higher degree of confidence with any TPO Analyzer or TPO method. Other benefits of the new TPO reference are:

- Identification of installed Analyzers uncertainty and improvement in the Quality Control management.

- The evaluation of laboratory performance by collaborative and comparison studies.

- Better out-of-spec production management. It will be possible to manage the product compliance by using a rejection zone, instead of a fixed single limit as it is widely used today.

The standard TPO analysis and its limitations

Having a robust reference for TPO provides the ability to evaluate the performance of the standard method for TPO analysis.

Differences between the standard TPO analysis method and the 6110 were found in the lab and in several plants. Nevertheless, the air injection reference gave the confirmation that the 6110 was providing the correct result. The standard TPO method is based on the assumption that a full equilibration of the package is reached after 5 minutes. This is not always true and the gap between theory and practice is generated by main factors like:

- Bottle turners are replaced by horizontal shakers

- The equilibration time is not the same for bottles and cans

- Foam inside the package reduces the turbulence generation

- Matrix effects, with or without oxygen scavengers, affecting the dissolved oxygen over the time

Final discussion

The air injection reference in cans provides significant progress when compared with other methods. The strength comes from its superior performances and the easiness of use and implementation.

Another benefit of the air injection method is because it mimics the same air contamination process during filling operations, with the main contribution of the oxygen into the headspace. The validation of a TPO method is then done with a package having very close conditions than those found after the filling process.

The air injection method has also highlighted limitations of the standard TPO analysis where the measurement of the dissolved oxygen after, a supposed perfect equilibration, leads to underestimate the TPO in many cases. The reason is the difficulty to get the correct oxygen transfer from the HS to the liquid; the equilibrium is almost never completely reached. Because 60% to 90% of the TPO is located in the HS, measuring the smallest oxygen content in the liquid exposes to a higher uncertainty when applying the Z factor.

The identification of the air injection reference performances have been made possible with the Orbisphere 6110 which does not require the need for equilibration.

Finally, the use of a robust TPO standard reference will also help the transition from existing devices using the standard method to new TPO Analyzers.

Additional Resources

Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

go to HACH.COMIntroduction When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Breaking Down Phosphorus Removal in Wastewater Treatment

go to HACH.COMEfficient phosphorus removal is a complex yet essential process for wastewater treatment facilities that have regulatory requirements. Facing fluctuating influent conditions, operational cost pressures, and regulatory requirements, many facilities...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.