RTC-DAF Automatically Adjusts Polymer and Coagulant Dosage

Problem

A chemical supplier of a large North American pulp and paper plant was looking for a ready-to-use system package to automate the polymer and coagulant dosage of two whitewater save-alls (DAF).

Solution

The Hach® Real-Time Control module for dissolved air flotation (RTC-DAF) offers a real-time polymer/coagulant analysis and optimizes dosages. This allows the facility to monitor and remove solids without over-dosing chemicals in the DAF.

Benefits

- RTC-DAF helped this chemical supplier to easily implement an automated polymer/coagulant dosing control with their existing pump skids.

- The system was implemented with minimal use of plant resources.

- No I/O from the plant’s SCADA was required.

Background

Like many pulp and paper plants, this one uses save-alls in the secondary water loop to recuperate the hot water and fibers from the whitewater chest overflow. The save-alls are dissolved air flotation equipment that use coagulant and polymer to increase the particle size of the solids that have passed through the paper machine wire. Micro-bubbles attach to the particles, causing the suspended solids to float to the surface where they are skimmed off and recuperated in the blend chest. This process clarifies the process water before it is re-used in the low-pressure showers of the paper machine.

Chemical Supplier Challenges

The challenge of the chemical supplier was to integrate an automated dosing system while using minimal resources from the mill. The control system of the mill was already at capacity, with no I/O available for the new controls. The mill is very busy, so the availability of their personnel to install and program a control system was limited—making a standard, easy-to-implement system critical.

Solutions & Implementation

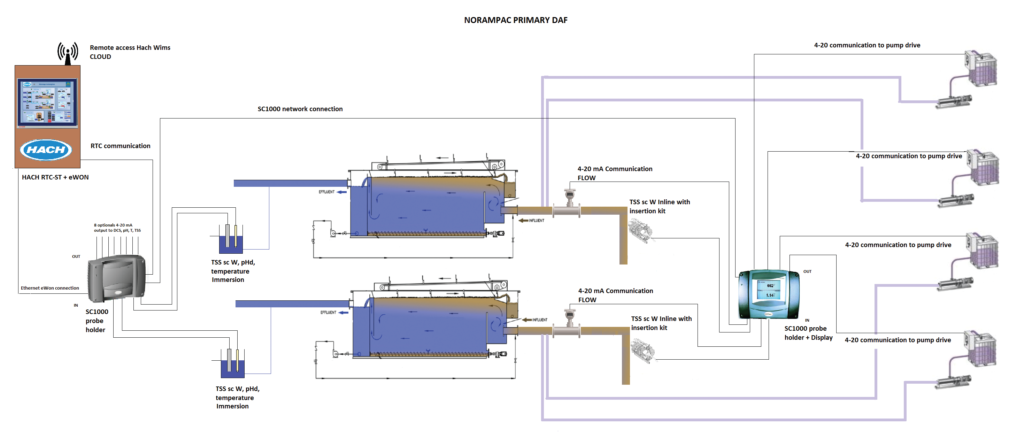

To help ensure a proper chemical supplier transition, Hach was asked to provide a standardized control solution, as well as support in the installation, commissioning, and optimization phases of implementing that solution.

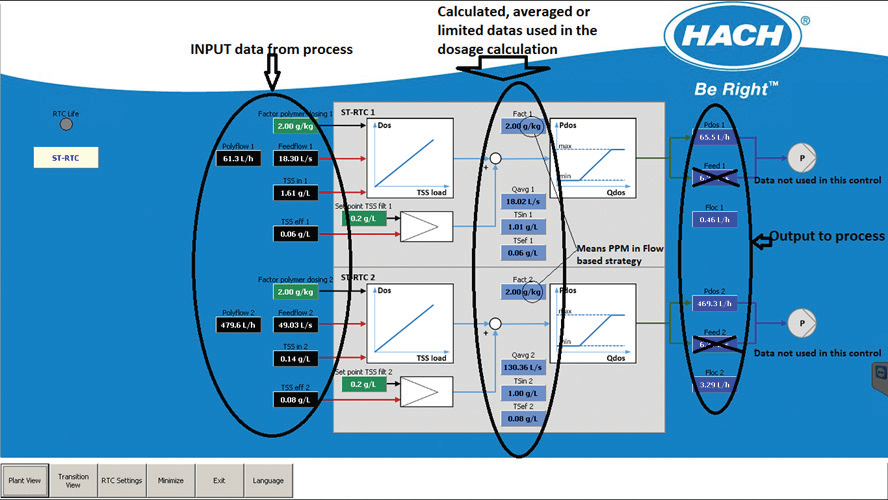

A service contract with Hach’s specialized RTC technical support team provided personalized implementation support. A Hach project manager was dedicated to supporting the customer step-by-step from initial configuration and start-up to ultimately fine-tuning and optimizing the process for their facility. The initial control strategy was based on flow as a feedforward loop for the polymer and the coagulant was added based on a ratio from the polymer dosage. Eventually, the plant has the option to optimize the dosage based on the quality of the filtrate as a feedback PID control setpoint. All the setpoints and configurations of the control can be limited inside a dosage range determined by the operators.

Because temperature also greatly influences the process, the plant decided to install Hach’s high-temperature capacity TSS HT probes. These probes were immersed in sampling pots at the inlet and outlet of the DAF, and inform the RTC module as it determines the optimal dose.

Conclusion

With the support of Hach, the chemical supplier of this large North American pulp and paper plant was able to easily implement the RTC-DAF to automatically control their coagulant and polymer dosage, resulting in additional resource savings moving forward.

Additional Resources

Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

go to HACH.COMIntroduction When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering...

Maximizing Phosphorus Removal

go to HACH.COMPhosphorus removal plays a critical role in protecting waterways, meeting permit requirements, and managing treatment costs. But optimizing phosphorus treatment isn’t always straightforward, especially when processes, influent conditions, and system...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.