Too Small For a Sludge Age Controller?

The 100,000 gallon per day Morrison Wastewater Treatment Plant says “No!”

In March of 2010, the staff at the wastewater treatment plant in Morrison, Colorado created an automatic sludge age control system that automatically wasted pounds of sludge based on a sludge age set point entered in the SCADA system by the operator. After more than two years of operation, the performance of the automatic sludge age control system can be evaluated.

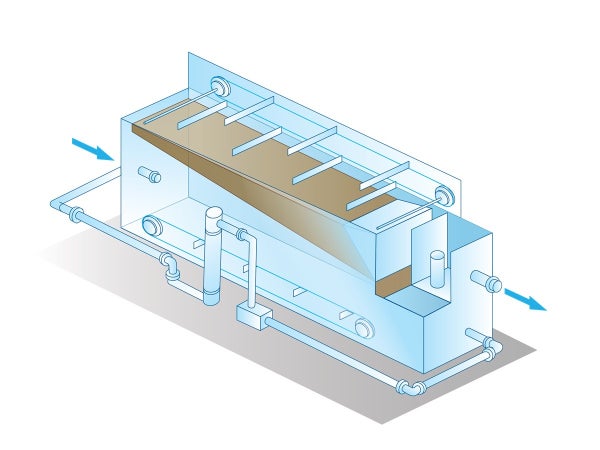

The town of Morrison, Colorado operates an extended aeration-activated sludge treatment system designed to handle 200,000 gallons per day of flow. Currently, the system is operating at less than capacity. The treatment plant consists of screening, grit removal, aeration, clarification, sodium hypochlorite disinfection, de-chlorination, aerobic digestion, sludge holding, and drying beds.

The heart of the sludge age controller is comprised of two Hach® SOLITAX suspended solids sensors connected to one common Hach sc digital controller. One sensor is inserted into the combined return activated sludge/waste activated sludge (RAS/WAS) pipe, and the other is immersed into the mixed liquor in the aeration basin. When the sludge age set point is entered into the SCADA system, the controller reviews the previous 24 hours of mixed liquor concentration data, and then determines the pounds of solids to waste in order to meet the sludge age set point. Once that number is determined, the controller executes a timed wasting event where the concentration of solids and waste sludge flow are monitored and recorded every five seconds. At the end of the wasting event, the total pounds wasted in that event is calculated. The timed wasting events continue throughout the day until the correct number of pounds of solids are wasted.

The sludge age controller was implemented in order to automate the wasting process so that it was not necessary to spend two hours a day manually wasting sludge, and to help the operator better control the treatment process. Previously, the results from suspended solids grab samples would arrive three days after the samples were taken. Now, the staff can view the suspended solids and sludge age data in real time, which allows greater transparency of the process. Always searching for ways to improve their system, the staff have found ways to adjust the controller to produce additional, unexpected benefits.

The largest unexpected benefit is that from March of 2010 through May of 2012 (the study period focused on here), Morrison did not have to haul away any sludge from their sludge holding tanks. Before the controller was installed, they had to pump out the sludge holding tanks on average every three weeks, due to overwasting and overloaded sludge drying beds. By using the controller to waste thicker sludge, they are able to process the biosolids with their existing solids handling system, and they no longer need to pump out an overflowing sludge holding tank. Over the two years, at $28 per wet ton, the savings are estimated to be $63,000, which is significant for this small facility.

| Cost per Wet Ton | Hauling Events Avoided | Total Savings |

|---|---|---|

| $28 | ~90 events (average every 3 weeks over 2 years) | $63,000 |

The staff has also improved the operation of the controller by using the real-time data to know when the solids concentration in the RAS/WAS is “high” (above 9,000 mg/L), so they can execute a wasting event. This wastes thicker sludge and less water, which means that they won’t have to call the sludge hauler for the foreseeable future, even if plant flows or sludge yields increase.

Other benefits that the staff have discovered include:

- Reducing operator error (especially error between operators).

- Reducing overwasting events which would fill the digester to capacity.

- Ability to operate at a higher sludge age, which reduces the sludge yield.

- Creating a more consistent operation without large swings.

Maintenance of the system includes periodic manual cleaning of the sensors “when the data looks odd,” and verifying that the sensors are reading correctly by taking a comparison sample every six to eight months. The sensors have built-in wipers that keep the optics clean, which allows for months to pass between manual cleanings.

The staff agree that the sludge age controller has been a worthwhile investment. The savings in initial cost, operational costs, and time documented over the years have convinced the staff at Morrison that even for small wastewater treatment plants, automating processes can have big benefits.

Additional Resources

Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

go to HACH.COMIntroduction When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering...

Maximizing Phosphorus Removal

go to HACH.COMPhosphorus removal plays a critical role in protecting waterways, meeting permit requirements, and managing treatment costs. But optimizing phosphorus treatment isn’t always straightforward, especially when processes, influent conditions, and system...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.