Using Liquid-Phase H2S Measurement To Protect Sewer Networks and Workers

While the estimated service life of steel-reinforced concrete pipe carrying stormwater can be 100 years, sanitary-sewer networks have a lot more working against them. Here are multiple considerations for using liquid-phase measurements to quantify hydrogen-sulfide (H2S) concentrations more consistently, identify potential threats to worker health and infrastructure longevity, and support better strategies for mitigating those risks.

The Hydrogen-Sulfide Problem in a Nutshell

Perhaps the most prominent issues that come to mind when discussing H2S concentrations in wastewater collection networks are customer complaints about odors and worker-safety issues when working in hazardous enclosed spaces. But the total story extends even beyond that, into the out-of-sight, out-of-mind realm of underground infrastructure.

According to this U.S. EPA document on hydrogen sulfide corrosion and its consequences, “Hydrogen sulfide corrosion in wastewater systems often results in costly, premature replacement or rehabilitation of systems used in the transport and treatment of wastewater. Sewers designed to last 50 to 100 years have failed due to hydrogen sulfide corrosion in as little as 10 to 20 years. Electrical and mechanical equipment with an expected source life of 20 years has required replacement in as little as five years.”

Keeping A Closer Eye On High-Profile Locations

Key areas for monitoring H2S presence include collection-network force mains with anaerobic conditions and lift stations or wet wells where turbulence exacerbates H2S odor problems and enclosed spaces pose dangers for maintenance workers. The extent of monitoring will depend on how many lift stations, wet wells, and miles of force mains there are in the system, and on the hydraulic retention times (HRT) for each of them.

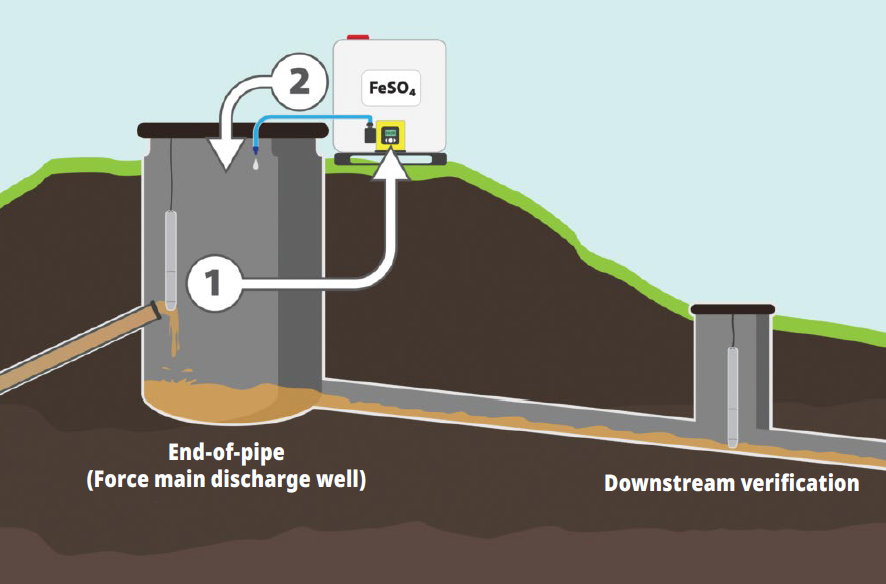

Using liquid-phase sensors (Figure 1) offers multiple advantages in terms of more versatile mounting options and more appropriate representation of H2S concentrations. They can range from simply knowing wastewater hydrogen-sulfide concentrations to monitoring system corrosion to adjusting wet-well or force-main HRTs to dosing chemicals to neutralise the H2S.

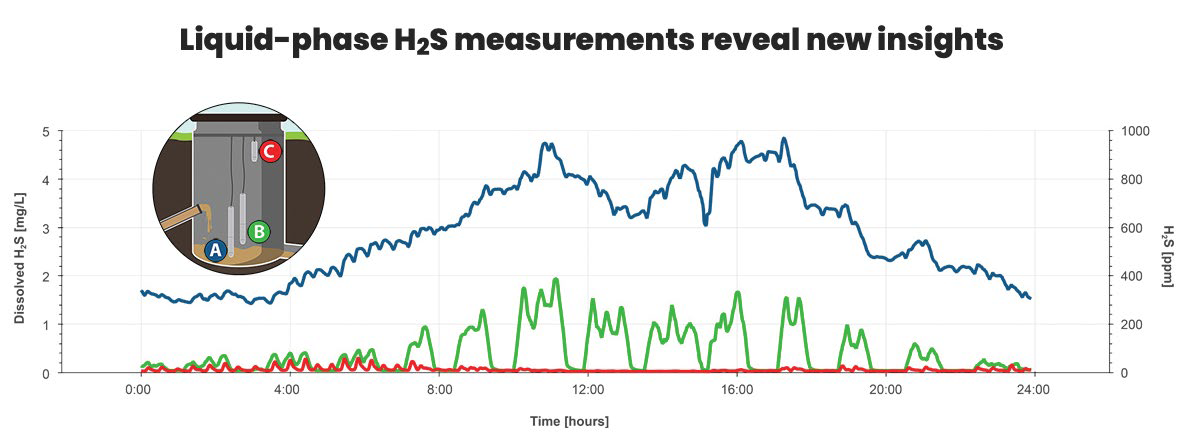

Remotely monitoring accurate measurements from multiple locations on a single dashboard can go a long way toward reducing downstream problems with the most cost-effective treatments available. Getting a true picture of the extent of the problem in order to evaluate the appropriate decision-tree options for treatment starts with more accurate detection closer to the cause of the problem (Figure 2).

Added Versatility, Improved Understanding

Comparing the improved opportunities offered by portable, liquid-phase H2S sensors reveals cost-saving and operational-improvement benefits.

- Continuously measuring H2S directly in the water provides an instant, accurate value for the highest potential concentration at that specific point in the collection network – as compared to readings taken in the air above. It can also eliminate chemical-dosing lag time between a significant change of hydrogen-sulfide concentration and the point where that is detected by a gas-phase sensor mounted high in a manhole structure (Figure 3 see next page).

- The capacity to move a sensor quickly from location to location speeds the ability of a short-term measurement campaign to survey potential new problem areas throughout the network – more efficiently and affordably than grab-sampling.

- Optimising conditions in the collection network also provides benefits for cost-effective performance efficiency downstream in the network or the wastewater treatment plant (WWTP) itself. For example, overdosing nitrate in the collection network might address hydrogen-sulfide concentrations there, but incur added costs to remove the excess during the WWTP processes. Continuous hydrogen-sulfide monitoring can minimise that risk.

- Also, when a single, portable, remote sensor offers flexibility for both gas-phase and liquid-phase sampling, it can help to pinpoint the source of a specific odor complaint and then quantify the exact levels of odor-causing H2S in the wastewater at that location.

Gaining Operational Benefits

Short-term and long-term monitoring data can help to inform the analyses required for chemical-feed optimisation, siting of dosing stations, informing consults relative to future planning of new collection-network designs, etc. And once the best locations for permanently mounted sensors are identified, measuring H2S in the wastewater there requires relatively few liquid-phase sensors as opposed to a fleet of gas-phase sensors that need to be rotated in and out on a periodic basis. Here are some common wastewater-collection-network applications that benefit from continuous liquid-phase monitoring:

- Troubleshooting Odor Complaints. The ability to identify actual H2S concentrations – or the lack thereof – in areas of customer complaints helps utilities resolve problems quickly or prove to the complainant that odors are being caused by conditions outside the wastewater collection network.

- Identifying Potential Corrosion Issues. Continuous monitoring at key locations – outlets from force mains, wet wells where water turbulence releases H2S from the water into the air, and sewer lines leading to the WWTP – enables utilities to neutralise the potential for corrosion before concrete or metallic infrastructure is compromised.

- Optimising H2S Chemical Dosing Control. Managing chemical dosing based on continuous real-time readings of changing diurnal flow characteristics enables utilities to match the exact chemical dosing needed. That saves the expense of overdosing and minimises the risk of biological process upsets.

- Refining Collection-Network Maintenance Strategies. Continuous monitoring of H2S levels also makes it easier to monitor potential rates of deterioration in collection-network infrastructure and adjust related maintenance scheduling. That includes using those readings to complement video inspections in identifying whether deterioration is accelerating or not. It can even include reducing the frequency of jet-cleaning and inspections based on low H2S concentrations.

- Monitoring Increased Loads From New Construction. Because adding new hookups to an existing sewer system can change the dynamics of operation, monitoring water composition in areas of new construction can quickly identify where operational changes are required.

- Coordinating Among Regional Utilities. When regional treatment plants accept inputs from multiple decentralised wastewater districts, monitoring H2S in the separate inflows can make an important difference in coordinating how individual sources and combined flows are handled.

- Setting Industrial Wastewater Rates Fairly. Monitoring the inflow from industrial customers who discharge wastewater with higher-than-normal concentrations of H2S can help utilities establish more favorable rates for treating the discharge as it is or convince those customers to perform appropriate pretreatment interventions.

Additional Resources

Pairing Digital Flow Sensors with the Hach AS950 Automatic Sampler

go to HACH.COMIntroduction When the Hach® AS950 Automatic Sampler launched in 2015, we were excited to offer the option to connect digital flow sensors to the controller. Digital flow sensors can be used for collecting flow proportional samples, as well as triggering...

Maximizing Phosphorus Removal

go to HACH.COMPhosphorus removal plays a critical role in protecting waterways, meeting permit requirements, and managing treatment costs. But optimizing phosphorus treatment isn’t always straightforward, especially when processes, influent conditions, and system...

Optimize Total Suspended Solids (TSS) & Turbidity Measurement

go to HACH.COMAccurate measurement of Total Suspended Solids (TSS) and turbidity is vital for effective water quality management across municipal, industrial, and wastewater environments. Real-time insights into solids concentrations empower operators to improve...

Privacy Policy | Cookie Policy | Cookie Settings | Do Not Sell or Share My Data

©Hach All rights reserved.